|

|

N

e w P r o d u c t s

|

|

Add

a New Product

|

|

Mead

Introduces New Isonic� Valve Mead

Introduces New Isonic� Valve

Mead Fluid Dynamics, a Bimba Company, announced today,

the arrival of the newest addition to the patented

Isonic� valve line, the V2 series.

The new V2 is a 2-and 3-way solenoid-operated,

direct-acting pneumatic valve. With

flow in the range of 0.01 to 0.05 Cv, the V2 is

available with multiple voltage and

electrical connection options in both normally-closed

and normally-open styles.

At the heart of the V2 is the award-winning Isonic�

design, which enables flow

channels to be molded directly into polymer body

sections. This eliminates the abrupt

air path changes associated with cross-drilled machining

in traditional valves. The

resultant ribbon-like flow paths create near laminar

flow with little energy/pressure

drop through the valve. Built-in, push-to-connect

collets allow for simple tube and

manifold connections in seconds.

To view the V2 valve system in action, including “how it

works,� and the snap-

on/quick-release manifold, visit

bimba.com/MeadV2.

About Bimba:

Bimba Manufacturing is a forward-thinking innovator of

actuation technology,

specializing in providing cutting-edge solutions to

engineering challenges. Its

capabilities include an extensive line of

industry-leading air cylinders, rotary

actuators, linear thrusters, rodless cylinders, flow

controls and position-sensing

cylinders. In addition to its broad line of standard

catalog products, Bimba also

develops many custom and semi-custom products designed

for specific customers and

applications. These products, used in machinery and

automation, are sold to original

equipment manufacturers and end-users throughout the

world in an expanding variety of

industries.

|

|

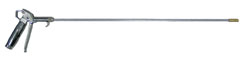

LONN

Manufacturing Co., Inc. FLEX IT’S ON... RELEASE IT’S OFF LONN

Manufacturing Co., Inc. FLEX IT’S ON... RELEASE IT’S OFF

Since 1940, the worlds most durable air savers, water

savers, cleaning guns, and

sanitizers. 1/2" OD linear design allows access other

blow guns can’t get to!

Perfect for tractor, combine and other hard to access

radiators, coolers, air filters

and interior spaces

90� AIR BLOW GUN AND LIQUID SPRAYER... SAME UNIT

Works with:

* Compressed air

* Building water pressure

* Pressurized chemicals

Features Include:

* Solid brasss extension & handle * 4 ply flexible

rubber body � 175 psi max

* 12", 24" and 36" lengths

* 12" and 24" extensions

WWW.LONN.NET

Toll free 888-898-5666

Fax 317-898-4561

E-mail INFO@LONN.NET

Made in U.S.A.

Since 1940, the worlds most durable air savers, water

savers, cleaning guns, and

sanitizers.

|

|

ENFINITY

SYSTEM PROPORTIONAL VALVE AND CONTROLLER FROM ENFIELD

TECHNOLOGIES ENFINITY

SYSTEM PROPORTIONAL VALVE AND CONTROLLER FROM ENFIELD

TECHNOLOGIES

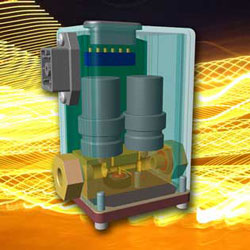

Enfield Technologies has introduced the Enfinity(R)

System for advanced proportional control. This system

comprises Enfield Technologies' M2 pneumatic control

valve and C2 controller.

The M2 is an instrument-grade, proportional, directional

control pneumatic valve that is designed for high

performance. This valve utilizes a specialized linear

force motor, as opposed to a traditional proportional

solenoid. The M2's aperture is controlled at a very high

speed, allowing the valve to respond quickly to

set-point command changes.

Enfield Technologies' C2 is an enclosed high-speed,

high-accuracy analog controller

with multiple PID and feed forward options. It includes

an intuitive, user-friendly

digital LCD/membrane keypad user interface. Independent

scaling of command and

feedback signals adds to the C2's flexibility.

Since both the M2 valve and C2 controller are available

with an integrated driver,

the user can choose to purchase an Enfinity System with

the driver included in either

of the two components. Although the Enfinity System is

ideal for users who want the

flexibility to create breakthrough applications, both of

its components can also be

purchased individually for use with other Enfield

Technologies products.

For complete technical data on the Enfinity(R) System,

please contact Enfield

Technologies by phone at (800) 504-3334 or by email at

info@enfieldtech.com.

Information on all of the company's products can also be

found on their website:

www.enfieldtech.com.

From: Enfield Technologies

35 Nutmeg Drive

Trumbull, CT 06611

Contact: George Haithwaite

Email: info@enfieldtech.com

Website: www.enfieldtech.com

Phone: (800) 504-3334

|

|

CLIPPARD

INTRODUCES NEW PUSH/PULL VALVES CLIPPARD

INTRODUCES NEW PUSH/PULL VALVES

Clippard Instrument Laboratory, Inc., introduces a new

line of manually-operated Push/Pull Valves.

These new spool valves are available in both 3- and 4-

way configurations. Available in detent or momentary

versions, these new valves provide the flexibility for

unlimited applications. And, with an operating

temperature of 32 to 140°F and an operating pressure of

0 to 115 psig, these new valves offer top notch

performance where maximum performance and maximum value

are demanded.

For complete details or to request a catalog, go to

www.clippard.com/pushpull-pol or call

1-877-245-6247.

Clippard Instrument Laboratory, Inc.

7390 Colerain Avenue

Cincinnati, OH 45239

513-521-4261

www.clippard.com/pushpull-pol

|

Spartan

Scientific Offers Effective Solution for Costly

Condensate Removal Spartan

Scientific Offers Effective Solution for Costly

Condensate Removal

The condensate removal season has arrived. To help the

compressor industry effectively and efficiently deal

with excess condensate removal, Spartan Scientific

offers the CRDV/S condensation removal drain valve.

Installed in conjunction with any compressor, air dryer

or drop leg, the CRDV/S is a set and forget device that

expels condensate from the air system upon the presence

of moisture, eliminating unnecessary compressor cycling,

reducing wear and tear on expensive components. Designed

to be user friendly and reliable, the CRDV/S uses a

state of the art temperature fluxuation circuit to

trigger a large orifice solenoid, to assure the

evacuation of all condensate eliminating costly air loss

or residual condensate left in the system which could

harm the downstream components. The rugged, modern

design of the CRDV/S features media compatible

materials, indicator lights to show purge cycles, and

incorporates an alarm function to alert in case of

malfunction.

The CRDV/S is proudly manufactured in the USA to ISO

9001 with the highest design quality standards. Complete

specifications can be found at www.spartanscientific.com or by calling Bob Howard

at 330-758-8446 x 122.

|

New

Compensation Units for Precise Handling New

Compensation Units for Precise Handling

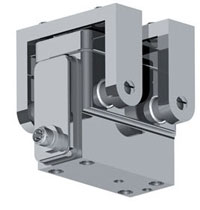

SCHUNK, Inc. is introducing two new compensation units.

The AGE-F compensation unit is self centering using

spring force and compensates for deviations up to 5mm in

the X- and Y-axis. Three different spring rates are

available for each of the four sizes, which can be

preloaded to specific values using an adjustment screw.

Equipped with cross roller guides, the AGE-F operates

purely mechanically, without any pneumatic elements.

This allows for smooth running, lower susceptibility to

wear and longer life. In addition, by being designed to

mount directly to PGN+ and PZN+ grippers and have robot

ISO flanges on the opposite mounting surface, the AGE-F

offers a very slim solution.

The AGE-E compensation unit utilizes elastomer pads

which allow the unit to compensate for deviations up to

4mm in the X- and Y-axis and angular compensation of up

to 3.5�. Also, the optional pneumatic centering lock

allows the unit to be held rigidly on-center when

needed. The AGE-E is available for direct mounting to

PGN+, PZN+, JGP and JGZ grippers from sizes 50 up to

200. Depending on the gripper being used, the maximum

handling weight the AGE-E can handle ranges up to 24 kg.SCHUNK Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560

Phone: 919.572.2705 or

800.772.4865

Fax: 919.572.2818

www.schunk.com

info@us.schunk.com

|

The

SuperStar .01 Micron Filter from LA-MAN The

SuperStar .01 Micron Filter from LA-MAN

LA-MAN � Corporation has a unique approach to providing

filtration for compressed air systems. The patented

series of SuperStar .01 Micron Filters are designed to

be installed at the point of use to efficiently remove

moisture and contaminants from air lines in order to

improve and extend the life cycle of tools and

equipment.

The innovative SuperStar .01 Micron Filter is a

four-stage filter designed to operate most effectively

within twenty-five feet of the point of use. By

incorporating a charcoal absorption element, the filter

offers a standard .01 Micron rating with flow ranges of

50, 75 or 100 SCFM and pressure ratings of 250psi. The

SuperStar .01 Micron Filter is an ideal solution for an

extensive array of applications that require the highest

standards of compressed air.

Additional standard features of the SuperStar .01 Micron

Filter include built-in differential pressure gauges and

Automatic Float Drain. The differential pressure gauges

provide a visual indication of required maintenance,

which is easily accomplished with the installation of

the appropriate service kit and without removing the

unit from the air system. The Automatic Float Drain

allows for the discharge of moisture from the SuperStar

.01 Micron Filter with no electrical requirements.

In addition to the complete line of SuperStar .01 Micron

Filter models; other compressed air filtration products

available from LA-MAN � Corporation include the

Extractor/Dryer Series, SuperStar Membrane Dryer,

Refrigerated Dryer, Pneuguard In-Line Dryer, and LA-MAN

Breathing Air Systems.

LA-MAN� CORPORATION

4400 Eastport Parkway

Port Orange, Fl 32127

Ph: 386-304-0411 800-348-2463

Fax: 386-304-0861 888-905-2626

www.laman.com

|

PIPE

LIFTER HANDLES MANY SIZES & MATERIALS PIPE

LIFTER HANDLES MANY SIZES & MATERIALS

A vacuum lifter for pipe that features curved foam pad

attachments to handle a wide variety of pipe from the

top surface, without slings or magnets, is available

from Anver Corporation of Hudson, Massachusetts.

The Anver VPE Pipe Vacuum Lifter features an electric

powered vacuum pump that accepts interchangeable pad

attachments to fit pipe from 3 to 36� O.D. and lengths

from 12 to 20 ft., with larger sizes up to 40 ft.

Constructed from closed-cell foam with an outside skin

and serrated edge which seals tightly against rough

surfaces, the pads can handle metals and plastics.

Equipped with an internal check valve to maintain a safe

vacuum level in the event of a power failure, the Anver

VPE Pipe Vacuum Lifter includes a front control panel

with easily accessible gauges, lights, power switches,

and an ergonomic handlebar that holds the control

pendant. Applications include hot-rolled metal-,

ferrous-, non-ferrous, and plastic pipe.

The Anver VPE Pipe Vacuum Lifter is priced from

$3,995.00 (list), depending upon capacity. Literature

and pricing are available upon request.

For more information contact:

Anver Corporation

Scott Dillon, Group Manager

36 Parmenter Rd.

Hudson, MA 01749

(800) 654-3500 FAX (978) 568-1570

e-mail: sdillon@anver.com

www.anver.com

|

Stainless

Steel Never Looked so Good...or so Affordable Stainless

Steel Never Looked so Good...or so Affordable

The Ashcroft� 1008S Stainless Steel Pressure Gauge

Tough environments and harsh media can quickly destroy

the wrong pressure gauge. That's why Ashcroft� puts

stainless steel to work in the Type 1008S. A stainless

steel sealed case and wetted parts along with the

patented PowerFlex� movement ensure a significantly

longer life and high reliability despite difficult

operating conditions.

Pointer flutter due to pulsation and vibration from

pumps or compressors is easily countered with the

patented PLUS!� option or by liquid filling. A ventable

plug allows the inside of the gauge to equalize with

ambient pressure to guarantee a stable zero indication

in low pressure gauges.

With both back and bottom connections and a variety of

inlet fittings to choose from, the 1008S can be stem

mounted or easily installed in a panel opening via the

optional U-clamp or front flange case configurations.

Dial face diameters of 2�" (63mm) or 4" (100mm) and

ranges from vacuum through 15,000 psi make 1008S the

easy choice for nearly any application.

For more information about this and other Ashcroft

products, please call 800/328-8258 or visit

www.ashcroft.com.

|

| |

|

Swivel

Fitting Features Captured O-ring Seals Swivel

Fitting Features Captured O-ring Seals

Swivel Fittings alleviate the problem of tube alignment

and rotation

commonly found when using fixed barb fittings. The

unique design,

Patent #4,496,204, allows for 360� rotation and

incorporates captured double o-ring seals to prevent

leakage.

The fittings are available in black nylon or clear

polypropylene.

Five o-ring compounds are featured: Buna-N, Ethylene

Propylene,

Silicone, and Viton.

Air Logic, www.air-logic.com

Email airlogic@air-logic.com

Call (262) 639-9035 or (800) 558-5950

|

-

Healthier

lubricants now a standard Healthier

lubricants now a standard

Health of workers and the associated related

business costs are

important to plant owners. The mist/fog you see in

many industrial plants is, in many cases, the result

of the many lubricants and liquids being used in the

process

-

- Most plant managers in Canada now prefer to use

airline lube products proven to be healthier

alternatives.

PNEU-Green, available through leading pneumatic and

industrial

distributors, is considered the leading

biodegradable pneumatic

lubricant in Canada. Performance, cost, virtual

abscence of

imputities and aromatic molecules has made this the

premium choice for all plants.

For More Information:

Bill Milne

www.alexmilne.com

1-800-563-5947

|

Amisco

SpA introduces 15mm Pilot system in 12 and 24 VDC

voltages. Amisco

SpA introduces 15mm Pilot system in 12 and 24 VDC

voltages.

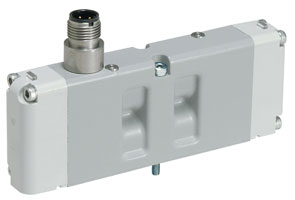

This versatile pilot system offers an M12 connector and

an IP 67 protection rate. Dimensionally compact and

designed for continuous duty, low power consumption,

reliability and high cycling rates.

Valve functions include: 3/2 NC, 3/2 NO, 2/2 NC & 2/2 NO

w/ 12-24 VDC and 25-115-230 VAC voltages. The Amisco

system is available in DIN 43650 C, AMP 2.8x0.5 and

flying lead connections.

Complete information about the specifications and

options can be found at www.amisco.it or by calling

484-753-4430.

|

SCHUNK

Products Certified for Use in Cleanrooms SCHUNK

Products Certified for Use in Cleanrooms

Many SCHUNK products can now be used in cleanrooms

without hesitation. This is confirmed by the certificate

issued by TÜV Süd (Technical Inspection Association in

South Germany).

The certificate confirms suitability for use in Class 5

cleanrooms according to ISO 14644. ISO Class 5 is

comparable to Class 100 of the US-Fed. -Std. 209, which

is no longer valid, but still frequently referred to.

SCHUNK succeeded in certifying entire series, instead of

just single products, as is often the case. Therefore,

the certificate covers all

versions and variants of the products. In particular,

the following series have been certified:

� PGN-plus parallel gripper

� DPG-plus sealed parallel gripper

� PZN-plus centric gripper

� DPZ-plus sealed centric gripper

� MPG miniature parallel gripper

� MPZ miniature centric gripper

� SRU rotary module

Customers and potential customers can request a PDF of

the certificate from SCHUNK, therefore eliminating the

need for certificates of

suitability for use or conducting measurements before

using products in cleanrooms. This saves time and money.

Initial measurements of SCHUNK grippers equipped with

additional HUE protective covers achieved excellent

results with ISO Class 2.

Although final certification is yet to be granted,

grippers with protective covers are already available

from SCHUNK.

SCHUNK Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560

Phone: 919.572.2705 or

800.772.4865

Fax: 919.572.2818

www.schunk.com

info@us.schunk.com

|

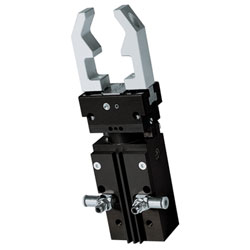

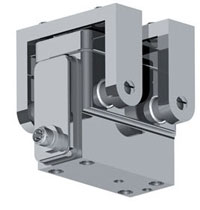

The new launch

with still wider jaws: FIPA gripper GR04.130F The new launch

with still wider jaws: FIPA gripper GR04.130F

FIPA Inc. supplements its 130 range of grippers

FIPA Inc. has supplemented its comprehensive range of

grippers: The gripper GR04.130F launched recently has

jaws that are wider than those

of the other models in the 130 range of grippers to

provide a secure grip. And: An inductive sensor provides

a feedback signal � and,

thus, achieves enhanced process safety.

The 130 family of grippers are characterized by powerful

gripping of die-cast parts in the injection molding

industry. These grippers

exert tremendous forces as a result of the dual

principle of operation and two large pneumatic plungers.

Qualities that are a standard feature of FIPA products:

Robust design, reliable in the production process �

quality for long-term use.

These grippers rarely need to be replaced and last a

long time. The high degree of wear resistance is ensured

by means of the hard-coated

surfaces of the grippers and the gripper jaws.

All grippers of the 130 family are very light and

provide a secure and reliable hold on any work-piece as

a result of the cogged surface

of the gripper jaws. Slippage is ruled out. The

extremely high retention force of 95 N does the rest.

Pick-and-Place solutions: FIPA products are combined

using the building block system. The recently launched

GR04.130 gripper forms a part

of it. Threaded and compressed air connections are

compatible with the other products constituting the

modular system of FIPA.

FIPA Inc.

5000 West Park Drive, Suite 100

Atlanta, GA 30336

Phone: +1 (800) 9137002

Fax: +1 (678) 5289530

http://www.fipa.com

|

Compact

Pressure Sensor SPAB for Compact and Easy Operation Compact

Pressure Sensor SPAB for Compact and Easy Operation

Festo is pleased to announce the addition of the Compact

Pressure Sensor SPAB to our product offering. This

inexpensive, compact pressure sensor is unique in its

outstanding ease of operation and compact size. It’s

simple to set up, install, and commission. Ideal for use

in medical and semiconductor applications.

Features:

� Compact Size: de facto-standard of 30mm x 30mm

� Pressure measuring range of 0 to 10 bar or -1 to +1

bar

Wide Diversity of Variants

� NPN or PNP switching outputs

� Digital and analog outputs

� M8 or cable electrical connection

� Worldwide fitting options: NPT, G and R threads

Easy to read

� Clear cut switching status display

� Two-part, three-color display

Quick copying

� Easy transfer of program to all other SPAB pressure

sensors

For more details, please visit:

www.festo.com/us/spab

Festo is a leading global manufacturer of pneumatic and

electromechanical systems, components and controls for

industrial automation, with 56 national headquarters

serving more than 180 countries. For more than 80 years,

Festo has continuously elevated the state of

manufacturing with innovations and optimized motion

control solutions that deliver higher performance, more

profitable automated manufacturing and processing

equipment. Our dedication to the advancement of

automation extends beyond technology to the education of

current and future automation and robotics designers

with simulation tools, teaching programs, and on-site

services.

Festo Contact Information for publication:

Tel: 800.99.FESTO; Fax: 800.96.FESTO

E-mail: customerservice@us.festo.com

Website: www.festo.com/usa

|

Reduce

installation time and costs with Balluff’s new V-Twin�

Magnetic Field Sensor Reduce

installation time and costs with Balluff’s new V-Twin�

Magnetic Field Sensor

Balluff has expanded its magnetic

field sensor portfolio with the new V-Twin - two

sensors, one connector.

This revolutionary low profile design allows the user to

reduce installation time and cost by requiring only one

four conductor cable with either M8 or M12 connections

for two end of stroke sensors. Because the BMF V-Twin

has just one connection for two sensors, it is ideal for

detecting multiple positions on pneumatic grippers and

cylinders and doubling the number of sensors in a

multiple interface box.

For further information, visit: http://www.balluff.com/V-Twin

The new BMF V-Twin is available in several sizes and

form factors to cover applications from grippers and

short stroke cylinders to C-Slot, T-Slot round and tie

rod cylinders, in some cases without requiring

additional mounting brackets. Weld field immune versions

are also available.

The Balluff V-Twin magnetic field sensors use

magneto-resistive technology to detect the piston magnet

through the aluminum wall of the cylinder. Advantages of

Balluff magnetic field sensors include universal

compatibility with either "Hall Effect" or "Reed Switch"

cylinder magnet polarizations, reduction or elimination

of double switch points, higher noise immunity, and

elimination of electrical contact wear and sticking.

Balluff magnetic field sensors come with short circuit,

overload, reverse polarity protection and a lifetime

warranty.

Balluff Inc.

8125 Holton Drive

Florence, KY 41042

|

Venturi

Vacuum Pumps FROM Anver Feature Energy-Saver Version Venturi

Vacuum Pumps FROM Anver Feature Energy-Saver Version

A full line of compact, air-powered single stage vacuum

generators that are offered in a wide range of

configurations for pick-and-place applications is

available from ANVER Corp. of Hudson, Massachusetts.

ANVER JB Series Single Stage Vacuum Pumps are

air-powered venturi style pumps that incorporate

one-piece anodized aluminum bodies, brass internal

nozzles, and achieve a 27� Hg vacuum with low flow rates

from 1.2 to 9 CFM. Featuring an energy-saver version

which has an air supply control valve, check valve and a

fast-acting switch to maintain a programmed vacuum

level, these modular vacuum generators are offered in a

variety of standard sizes.

Allowing system builders optimum flexibility, ANVER JB

Series Single Stage Vacuum Pumps can be configured with

electric or pneumatic pilots, supply and blow-off

control valves, dual ports, mufflers, vacuum port

extensions, gauges, and a host of other accessories.

Ideally suited for pick-and-place applications, they are

designed to be located close to the pickup point.

Contact

Anver

|

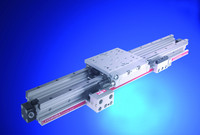

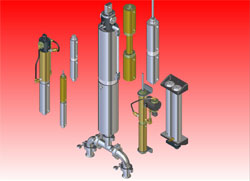

Performance,

Ease-of-Use and Reliability for the Most Demanding

Actuator Applications with Parker-Origa System Plus Performance,

Ease-of-Use and Reliability for the Most Demanding

Actuator Applications with Parker-Origa System Plus

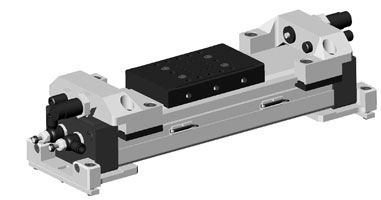

Richland, MI, June 1, 2009 � The Pneumatics Division of

Parker Hannifin announces the addition of three new

product lines featuring the Parker-Origa System Plus (OSP)

family of linear actuators. The OSP product line

includes the completely modular and space saving OSP-P

rodless pneumatic cylinders and the high speed precision

OSP-E electric linear drives. Complimenting the OSP-P,

Parker-Origa is also offering a range of linear rails

and cassettes.

The OSP-P rodless pneumatic cylinders manage high loads

and moments, equal force in both directions, service

intervals up to 8000 kilometers and include an internal

guide system. These cylinders have an aluminum extruded

profile with double dovetail mounting rails on three

sides enabling direct attachment for all modular

options. This allows customers to build flexible,

easy-to-install solutions such as extremely long

cylinders with stroke lengths up to 40 meters.

“This OSP-P fits a wide range of loads, speeds and

motion profiles," explains Cathy Laskero, Product

Manager for Parker-Origa. "Features such as its low

profile carriage design, adjustable end cushions, and

versatility make it perfect for any application.

Customers can choose from clean room applications,

stainless steel versions, special high and low

temperature models, high and slow speed � the OSP-P is a

multi-talented cylinder."

A full range of linear rails and cassettes options

accompany the OSP-P. "The OSP-P is truly the most

convenient and adaptable cylinder on the market with its

range of accessories and design options. Choices such as

roller bearing guides and passive and active brakes

along with accessories such as T-Slot and Adaptor

profiles, multiplex connections, inversion mounting and

magnetic switches make this rodless cylinder ideal for

point-to-point operations and a variety of standard and

custom installations."

The OSP-E electric linear drives offer either a toothed

belt or a screw drive for heavy duty linear and

multi-axis applications. The OSP-E with toothed belt

features an integrated recirculating ball bearing guide

ideal for lifting movements in multi-axis systems. It is

offered in 25, 32, and 50 millimeter (mm) sizes with

speeds of 5 meters/second (m/s) and stroke lengths

ranging from 5000mm to 7000mm. The toothed belt version

provides high acceleration and speed, a magnetic switch

set for contactless position sensing, and the option of

clamp or plain drive shaft. The OSP-E with either the

ball screw or trapezoidal screw drive option offers the

best solution depending on the application's need for

accurate positioning, high action forces and superior

running performance. Customers can select 25, 32 and 50

mm sizes, speeds ranging from 1.25 m/s for the ball

screw and 0.125 m/s for the trapezoidal screw with

stroke lengths up to 500mm.

"The OSP-E electric belt drive is ideal for high speed

applications, accurate path and position control and

longer strokes, while the electric screw drive version

offers the same accuracy and positioning with high force

capability," says Laskero. "Whether the application

requires a pneumatic or electric actuator, if a customer

wants high performance, ease of use, and reliability,

the Parker-Origa System Plus provides the best solution

and support on the market for linear drive systems."

The OSP-P rodless cylinders and linear guides are

available now from Parker-Origa. The OSP-E electric

linear drives will be available later this year. For

more information on the Origa System Plus, please visit

www.parker.com/pneu/rodless.

|

COOLING

TOWER REDUCES MEDIA TEMPERATURE BY AS MUCH AS 260�

CELSIUS (500� FAHRENHEIT) COOLING

TOWER REDUCES MEDIA TEMPERATURE BY AS MUCH AS 260�

CELSIUS (500� FAHRENHEIT)

The Winters SCT Series Cooling Tower is designed

specifically to protect pressure instruments in high

temperature applications. It works by utilizing “heat

exchange� technology in the same way radiators do.

The cooling tower is mounted in between the pressure

measuring instrument and process. Hot media from the

process will flow through the cooling tower’s stainless

steel spiral capillary. As it does, air will circulate

through the cooling tower’s vented body, passing over

the capillary. Heat transfer from the capillary to the

air will occur, lowering the temperature of the media

before it arrives at the top of the cooling tower and

instrument.

Winters� SCT Series Cooling Tower can significantly

reduce media temperature, thus protecting the instrument

and extending its service life. It is suitable for media

temperatures up to 300°C (570°F), and may lower them by

as much as 260°C (500°F) depending on the ambient

temperature. The cooling tower can be used with a

diaphragm seal.

Winters Instruments is a global manufacturer of pressure

and temperature instrumentation, with distribution in

over 80 countries. Go to www.winters.com to view our

extensive list of products and distributors, or call

1-800-WINTERS for more information.

|

Introducing

The POD Series Vacuum Generator Introducing

The POD Series Vacuum Generator

The POD is a vacuum cup platform that has a built-in

vacuum generator. All that is needed to vacuum energize

your cup is to connect a compressed air tube to the

one-touch fitting on the pod. Once bolted to your

tooling plate the POD performs two functions. The sturdy

POD platform holds your cup and is capable of

withstanding impressive loads. The internal vacuum

generator creates vacuum and is efficient yet stingy on

air consumption. Efficiencies are very high since the

vacuum is generated at the point of application. An

array of these devices is a great substitute for costly

centralized systems.

This is a flexible device for your lifting needs that

delivers design simplicity and savings.

Diameter: 2.10 in.

Screw size: 8-32 (4)

Ports: 1/4 tube one touch (air) 1/4npt (vacuum)

Mat’l: Aluminum or Acetal

POD Series Vacuum Generator and Vacuum Cup Platform:

Part# Air Consumption Vacuum Level @ 65psi

POD-1 0.6 scfm 20 in-Hg

Pneumatic Vacuum Innovations

888-281-4784

|

Jenny

Products, Inc. Offers New Compressor/Generator

Combination Units Jenny

Products, Inc. Offers New Compressor/Generator

Combination Units

SOMERSET, Penn. � Jenny Products, Inc introduces two

compressor/generator combination models, providing both

portable air and a power source in one versatile machine

for a variety of industrial, construction and

do-it-yourself applications.

The K11HGA-17P-3000W features Jenny’s renowned “K� pump,

a heavy-duty, single-stage cast-iron compressor pump.

The unit is powered by an 11-horsepower Honda GX series

OHV engine with electric start and produces 8.9 CFM @

100 PSI or 8.6 CFM @ 125 PSI for quick recovery.

Featuring a “G� pump and a 13-horsepower, electric start

Honda GX engine, the G13HGA-17P-3000W delivers 16.2 CFM

@ 100 PSI or 15.6 CFM @ 125 PSI.

Each model includes a 3,000-watt, 115V/230V generator,

providing a convenient solution for powering electric

tools, lighting or other jobsite equipment, or as a

backup power source during instances of power failure.

The compressor/generator units are offered with

17-gallon (64.3 liter), powder-coated, ASME certified

air tanks. Manoeuvring is simple with lifting handles

integrated into opposite ends of the compressors�

frames, and pneumatic tires are included to further

enhance portability.

Each compressor/generator model is equipped with

numerous standard features for increased uptime and

reduced maintenance. The compressors are belt driven

with a large flywheel for easy start-ups and extra

cooling, and a directional air shroud helps further

reduce pump temperatures. Special unloading valves on

the compressors also assist in engine starting.

Additionally, the units come equipped with a totally

enclosed heavy-duty belt guard, anti-vibration feet for

smoother operation, a large canister intake filter with

replaceable elements, manual tank drains, a

stainless-steel braided discharge hose, pressure relief

safety valve, regulator and outlet pressure safety

gauges.

Each unit is filled with Jenny “Ultimate Blue� synthetic

compressor-pump oil for its splash lubricating system,

ensuring complete oil coverage on the pistons,

crankshaft, bearings, rings and cylinders. The

compressor/generator combination units also come with an

optional lubricator, airline filter and oil-sight glass.

Other engine and pressure options are available upon

request.

With roots dating back to the 1870s, Jenny Products,

Inc. has been an OEM manufacturer for several major

manufacturers of air compressors. Today, Jenny

manufactures and markets its own line of hand-carry,

wheeled-portable and industrial-stationary air

compressors. For more information on its line of

equipment, contact Jenny Products, Inc., 850 North

Pleasant Avenue, Somerset, PA 15501-1069, call

814-445-3400, fax 814-445-2280 or visit the Web site at

www.jennyproductsinc.com.

|

THE

EXTRACTOR/DRYER Series from LA-MAN CORPORATION THE

EXTRACTOR/DRYER Series from LA-MAN CORPORATION

LA-MAN � Corporation has a unique approach to providing

filtration for compressed air systems. The patented

series of Extractor/Dryers� are designed as a point of

use filter that efficiently removes moisture and

contaminates to improve and extend the life cycle of

tools and equipment.

The distinctive Extractor/Dryer� is a two-stage filter

designed to operate most effectively within twenty-five

feet of the point of use. Each model offers a standard

5-Micron rating with lower Micron ratings available.

With flow ranges of 15 SCFM to 2000 SCFM and pressure

ratings of up to 250 PSI, the Extractor/Dryer� is an

ideal solution for an extensive array of applications

including air powered tools, surface preparation, paint

spraying, powder coating, and pneumatic operated

equipment.

Additional standard features of the Extractor/Dryer�

include a built-in differential pressure gauge and weep

drain. The differential pressure gauge provides a visual

indication of required maintenance, which is easily

accomplished with the installation of the appropriate

service kit and without removing the unit from the air

system. The weep drain allows for a continual discharge

of moisture from the Extractor/Dryer� and may be

replaced by either the addition of a float drain or

electronic drain valve for more precise control.

In addition to the complete line of Extractor/Dryer�

models, other compressed air filtration products

available from LA-MAN � Corporation include the

SuperStar Membrane Dryer, SuperStar .01 Micron Filter,

Refrigerated Dryer, Pneuguard In-Line Dryer, and LA-MAN

Breathing Air Systems.

LA-MAN CORPORATION

4400 Eastport Parkway

Port Orange, Fl 32127

Ph: 386-304-0411 800-348-2463

Fax: 386-304-0861 888-905-2626

www.laman.com

|

3

Jaw Pneumatic Angular Grippers have fail safe toggle

lock. 3

Jaw Pneumatic Angular Grippers have fail safe toggle

lock.

AGI a leader in motion control technology introduces the

latest technological advancement in three jaw pneumatic

angular grippers.

The AGA Series Angular Gripper Actuator features four

new models that have three jaws. The gripper jaws 180

degree opening is suited for applications which must be

performed within a limited work area. The AGA-23, 33, 43

and 53 series have stroke-limiting screws to adjust the

stroke between 0 and 180 degree. The four sizes have a

range gripping forces from 20 to 200 lbs.

When the jaws are completely opened, the work piece can

be placed in a fixture without having to retract the

gripper. This saves an extra step as well as the expense

of another axis of movement. The toggle mechanism

greatly increases in power as the jaws near the fully

closed position and become self-locking when past

parallel. The internal linkages are guided by two groves

that run the length of the body.

This will keeps the tooling jaws from loosing the center

repeatability. Close attention must be made to the

tooling jaws when designing them. Because the jaws swing

an arc, the mechanism produces higher velocity at the

end of your tooling during the stroke.

Therefore, tooling jaws should be short, lightweight as

possible, and flow controls are recommended. In cases

where longer jaws are needed, bumpers or miniature

hydraulic shocks should be used to decelerate the jaw at

the end of the stroke. All of these units are double

acting, have multiple airports, mounting locations and

available with sensor options for easy interfacing to

electrical controls.

AGI supplies a complete range of sophisticated

automation products that include: pneumatic parallel

grippers, rotary actuators, thrusters, linear actuator

slides, mini slides, tool changers, overload devices.

The units are available in imperial and metric versions

for flexibility and design for a world market.

For more information on this product, send for a FREE

catalog today.

For immediate assistance, call AGI, at (203) 459-8345 or

visit our web site at

www.agi-automation.com

|

New

Compact Explosion-Proof Current-to-Pressure Transducer

is Vibration and Position Insensitive New

Compact Explosion-Proof Current-to-Pressure Transducer

is Vibration and Position Insensitive

ControlAir Inc. is proud to announce the introduction of

the Type-595XP Explosion-Proof Current-to-Pressure I/P

Transducer. This unique current-to-pressure transducer

is small in size and light weight, yet is less sensitive

to shock, vibration and position change than other

I/P’s. The unit’s low power consumption, along with it’s

worldwide agency approvals for intrinsic safety and

explosion-proof, make it ideal for hazardous

environments in remote locations.

The unique conversion technology utilizing open loop

control provides a high level of regulation accuracy and

repeatability for the operation of actuated valves. A

low mass control circuit provides reliable linear output

in difficult applications at an economical cost. The

Type-595XP can mount in any position and is stable in

high vibration environments.

The Type-595XP holds agency approvals from Factory

Mutual (FM) and Canadian Standards Association (CSA) as

intrinsically safe and explosion-proof. It is also

compliant with the ATEX directive 94/9/EC for equipment

intended for use in potentially explosive atmospheres.

The unit is ideal for applications where power is at a

premium, such as, booster stations in remote locations

that often do not have access to compressed plant air

for operation of pneumatic valve actuators. Other

applications include valve control where the environment

can be hazardous, in such industries as, chemical,

petrochemical, paint, mining, and oil and gas.

ControlAir Inc.

8 Columbia Drive

Amherst, NH 03031 USA

Phone: 603-886-9400

Fax: 603-889-1844

E-mail: sales@controlair.com

Website: http://www.controlair.com

|

Herkules�

New Zero Level Lift & Tilt Herkules�

New Zero Level Lift & Tilt

Herkules Equipment Corporation’s New Zero Level Lift and

Tilt provides an easy method for loading material onto a

lift table using a pallet jack. No need to wait for a

fork lift or spend money on expensive floor excavation.

The lift’s platform is only 3/8� lowered and the lift

travels 25.5 inches. The tilt can be operated

independently of the lift, positioning materials

perfectly within the operator’s reach for better

ergonomics.

The 2,000 lb capacity lift and tilt is controlled easily

with a joystick controller on a pedestal. Roller wheels

are captured to prevent the lift table from tipping, and

internal anchoring holes are provided to secure the lift

to the floor. Safety skirting is available.

Herkules� engineering team can customize the Zero Lift

and Tilt to solve a customers� specific material

handling need. The platform dimensions, the tilt’s

retaining corners, and other features can be specified

into a design that provides a solution for improving the

customer’s productivity.

Herkules� pneumatic lift systems are virtually

maintenance-free, with no messy fluids or costly

cylinders to replace. The power source, Herkules� Air

Bag� technology, provides a patented direct one-to-one

lift ratio, eliminating stress on the scissors,

minimizing wear and maintenance. The lifting motion is

smooth and stable. The heavy-duty air bags are built for

rugged daily use giving facilities a lifetime of

trouble-free operation.

Herkules Equipment Corporation has been manufacturing

Pneumatic Lifting Equipment for over 20 years, including

(standard and custom); Lift Tables, Lift & Rotates, Lift

& Tilts, Human Lifts, Power Rotate Systems, Lifts for

Integration, Cart Positioners, Pallet Positioners, and

Vehicle Lifts.

For more product information, contact Herkules at

800-444-4351, or email info@herkules.us. Visit our

website at www.herkules.us

|

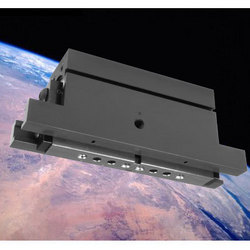

MATRIX

Ultra High Speed Proportional Flow Pneumatic Valves MATRIX

Ultra High Speed Proportional Flow Pneumatic Valves

MATRIX MULTI-VALVES are engineered lor the most

demanding OEM applications where ultra high speed,

perfect repeatability, uncompromising reliability and

ultra-long lile are ol the essence. These superbly

crafted valves are patented and currently in use in

Fortune 100 companies.

SOME OUTSTANDING FEATURES

•Ultra fast - response times as low as 0.1 mS

•Ultra robust - minimum operating life of 500 million

cycles

•Ultra compact - up to 9 valves in 2.5 cu. in.

•Ultra repeatable - works the same in cycle 1 to cycle

500,000,000

•Pressure and Vacuum valves available in 2/2 and 3/2

formats

•Proven insensitivity to vibration

•Multiple outlets with individual controls

•Low cost-in-use. Ideal for OEM's

David & David

17476 Winter Pine Way,

Canyon Country, CA 91387-6877

Phone: 661-299-2762

Fax: 661-299-2763

|

Proportion-Air

QL3: High Resolution Control at High and Low Flow Proportion-Air

QL3: High Resolution Control at High and Low Flow

McCordsville, IN � Today Dan Cook the founder and

president of Proportion-Air, Inc. announced the latest

addition to the product line, the new QL3 Pressure

Control Valve. The QL3 allows high volumes of air to

move quickly and precisely at pressures up to 150 psig

using proportional solenoid valves with a unique analog

PID circuit. Ideal for use with flow meters, it provides

high resolution and smooth pressure control at high and

low flow rates and avoids the “steps� prevalent in most

feed and bleed I/P’s. The output pressure is

proportional to the electrical input or command signal.

The QL3 improves and builds on the proven Proportion-Air

QB3 series� high performance using a current driven

variable orifice solenoid valve and the analog PID

circuit. The PID circuit integrates error out quickly

resulting in superior resolution. This combination of

the “stepless� solenoid valve with a high speed analog

PID on a high flow volume booster is what allows large

volumes of air to be moved with precision at a very high

flow rate.

The QL3 is also easily serviced. The volume booster is

designed so there are no stamped gaskets or special

molded diaphragms or seal parts. All of the parts

related to normal maintenance are standard o-rings.

Complete repair kits are available, but in case

emergency repair is needed parts should be available

from any fluid power distributor or even most

neighborhood hardware stores.

Proportion-Air’s electro-pneumatic controls have been a

staple of the industry for more than 25 years. Known for

engineering excellence, Proportion-Air prides itself on

solving its customers� most difficult problems. The

world wide headquarters is located in McCordsville,

Indiana. Please contact Proportion-Air via telephone at

317-335-2602 or e-mail at info@proportionair.com.

|

New extreme high volume blow gun from Coilhose New extreme high volume blow gun from Coilhose

This extreme high volume blow gun introduced as part of Coilhose Pneumatics� new Extreme Construxion Accessories� product line is as ergonomic as it is easy-to-use. Its Extreme Ease Trigger� is power-assisted and requires minimal force to actuate. This blow gun, with a 3/4� female inlet, is for use with tow-behind or large capacity compressors and conforms to OSHA standards. Available with 2�, 24�, or 48� safety extensions, or with a specially engineered multi-jet nozzle tip.

Coilhose Pneumatics

19 Kimberly Road

East Brunswick, NJ 08816

P: (732) 390-8480 ext.609

F: (732) 390-9693

-

|

UNIPLACE

2300/2400 - Handling System for Medical Technology UNIPLACE

2300/2400 - Handling System for Medical Technology

The SCHUNK UNIPLACE handling system is a cartesian arm

system with an innovative drive concept and compact

design.

The backlash-free system with three linear axes (UNIPLACE

2300), which can be optionally fitted with an additional

rotary axis (makes it a UNIPLACE 2400), is extremely

quiet and precise. In addition to the drive and the

control unit, it also contains a media feed-through,

which can be used to feed air, or for forwarding

electrical signals.

The linear axes have effective dust protection covers

and a sealed cover for the rotation axis and the control

unit so that the entire series can also be used in

applications with stricter requirements in terms of

freedom from dust or guaranteed hygiene. This makes the

UNIPLACE handling system suitable for applications in

laboratory automation, laser processing, medical

technology or for pick and place tasks with optional

optical inspection.

The UNIPLACE is easy to integrate in machines and

systems. It can also be used as a standalone system -

all that is required is power and a laptop (only for

programming, not for operating). The highly professional

software makes programming the system easy.

The UNIPLACE handling system allows a working area of up

to 1000x400x240 mm to be covered, and the precise

integrated distance measurement system with a resolution

of 8 µm allows a repeat accuracy of +/- 0.05 mm. The

UNIPLACE 2300 can move weights up to 5 kg; its sister

module UNIPLACE 2400, which is equipped with a rotary

axis, can cope with maximum loads of 3.5 kg, whereby the

maximum angle of rotation of the rotary axis is +/-270�.

The maximum speed in both versions is 1 m/s, and the

maximum acceleration is 3 m/s�.

- SCHUNK Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560

Phone: 919.572.2705 or

800.772.4865

Fax: 919.572.2818

www.schunk.com

info@us.schunk.com

-

|

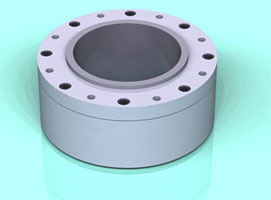

INDUSTRIAL

SANITARY GAUGE ASSEMBLY PROVIDES SAFE ALTERNATIVE TO 3A

APPROVED GAUGES INDUSTRIAL

SANITARY GAUGE ASSEMBLY PROVIDES SAFE ALTERNATIVE TO 3A

APPROVED GAUGES

Toronto, Ontario - Winters� PSI Series is a stainless

steel case gauge mounted to Tri-Clamp� sanitary style

seal that does not have process threads or an entry

point for the process media to

clog the seal. It is used to measure pressure on systems

with media that may clog instrumentation or solidify,

and is a cost-effective and viable solution when 3A

approved gauges are not required. It is CRN registered.

Viscous materials like paint, ink or heavy liquids often

solidify or build up around instrumentation. This causes

blockage, rendering the instrument useless or causing

false pressure readings. To prevent this, the PSI Series

has a stainless steel diaphragm seal welded to a

stainless steel dry gauge that can be liquid-filled.

Various fill fluids are available. The diaphragm seal’s

connection is available in a 1.5� (40mm) or 2� (50mm)

bottom or back Tri-Clamp� fitting. Choose from �1.5 or

�1% full scale gauge accuracy. This new gauge assembly

from Winters comes with either a crimp-on or bayonet

ring on the gauge.

Winters Instruments is a global manufacturer of pressure

and temperature instrumentation, with

distribution in over 80 countries. Go to www.winters.com

to view our extensive list of products and

distributors, or call 1-800-WINTERS for more

information.

Tri-Clamp� is a registered trademark of Tri-Clover, Inc.

Winters Instruments

121 Railside Road, Toronto, ON M3A 1B2

416-444-2345 / 1-800-WINTERS /

www.winters.com

|

MR

Flow Transmitter from Hedland MR

Flow Transmitter from Hedland

Racine, Wisconsin - The MR Flow Transmitter combines

state-of-the-art digital signal processing technology

with the rugged proven technology of a piston-type

variable area flow meter. The solid state design

electronically senses movement of the magnetic piston

assembly and provides accurate, repeatable flow

measurement. The device has NO mechanical linkages,

which results in longer operating life.

All MR Flow Transmitters come pre-calibrated from the

factory. However, the unit may also be configured by the

User to meet specific application requirements.

Calibration inputs are available for: specific gravity

for all fluids; viscosity for petroleum-based fluids; as

well as specific gravity, pressure and temperature for

pneumatic systems. Combined with User-selectable units

of measure, these configuration functions allow for

precise measurement on unique applications.

Additional benefits and features include:

� Non-contact sensor electronics

� Digital flow rate and total flow indication

� Proportional analog output

� CE compliant � exceeds US and meets European standards

from EMI/EMC

� Low power design allows for 2-wire loop powered

operation

The MR Transmitters provide voltage (0-5 VDC and 0-10

VDC) and current loop (4-20 mA) outputs, allowing for

easy electronic integration. Optional remote display and

signal processors are also available from Hedland.

The F6700/F6750 Series Digital Display with integrated

signal processor capabilities is offered to enhance the

utility of the MR Flow Transmitters. In addition to

remote flow monitoring, this unit can be configured to

provide alarm processing and communication modes,

including RS232, RS485, Modbus, Profibus and DeviceNet.

Hedland manufactures flow meters, flow switches and flow

transmitters for a broad range of industrial

applications. The Company offers products for use with

oil, air, water, and many other liquids and compressed

gases. For complete specifications on the MR Flow

Transmitter call 1-800- 433-5263, visit Hedland’s

website at: www.hedland.com, or e-mail questions to:

hedlandinfo@racinefed.com. Technically trained Inside

Sales

Representatives are available to assist in the selection

process.

|

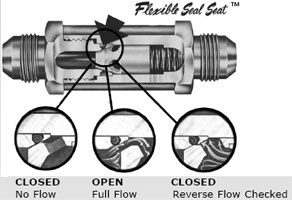

All

Stainless Steel VACUUM CHECK VALVE from Pneumatic Vacuum

Innovations All

Stainless Steel VACUUM CHECK VALVE from Pneumatic Vacuum

Innovations

This device allows high vacuum flow in one direction

while preventing return flow in the other direction. Can

be used as a non-return valve for maintaining vacuum in

vessels. The stainless steel construction allows the

device to be used in very corrosive environments. The

large 3/4 NPT porting and the large internal orifice

provide impressive flow rates. The low mass gate allows

any mounting position.

Specifications:

Outside Diameter: 42mm (1.63�)

Overall Length: 75mm (2.90�)

Porting (2): 3/4 NPT female

Flats: 36mm (1-7/16�)

Orifice Diameter: 18mm (.70�)

Maximum Vacuum: 10 torr (29.5 in-Hg)

Minimum Vacuum: 730 torr (1 in-Hg)

Cracking Vacuum: Approaching Zero

Body Material: 304 stainless Steel

Check gate material: Fiber reinforced neoprene

Seat Material: 304 stainless Steel

Pneumatic Vacuum Innovations

Brea, California

888-281-4784

http://www.pvi.com

|

New

AHP Series High Pressure Alloy Filters from Van Air New

AHP Series High Pressure Alloy Filters from Van Air

Lake City, PA, U.S.A. � Van Air Systems� introduces its

new AHP Series High Pressure Alloy Filters.

The New AHP Series from Van Air offers a unique range of

725 PSIG High Pressure Filters using machined or diecast

aluminum components. Offering many new design features

such as a push-in element design with double “O� ring

seals, silicone free construction and full corrosion

protection, these filters are designed for ease of use

and built to provide lasting service for your air or gas

system.

For more information on the AHP Series visit

www.vanairsystems.com.

Phone (800) 840-9906 or Fax (814) 774-0778 or E-mail:

info@vanairinc.com

CONTACT: Technical Sales

Van Air Systems

2950 Mechanic St.

Lake City, PA 16423

814-774-2631

800-840-9906

FAX 814-774-0778

www.vanairsystems.com

info@vanairsystems.com

|

Vacuum

Suction Cups Handle Extremely Hot Glass Vacuum

Suction Cups Handle Extremely Hot Glass

A new line of vacuum suction cups that are designed for

handling hot glass or metal objects in momentary

pick-and-place applications, without leaving marks, is

being introduced by ANVER Corporation of Hudson,

Massachusetts.

ANVER High Temperature Vacuum Suction Cups feature a

special Viton� fluorocaoutchouc FPM-F rubber pad with a

heat-resistant felt coating that will not mar material

surfaces. Capable of excursions up to 752°F (400°C),

these high heat-resistant vacuum suction cups are

designed for momentary pick-and-place applications with

hot glass, cookware, and metal objects.

Available in a 3.82� dia. O.D. size, with a G 3/8�

center port, ANVER High Temperature Vacuum Suction Cups

incorporate a metal mounting plate which firmly holds

the rubber and felt coated pad. Applications include

handling automotive windshields and all types of

tempered glass and cookware.

Contact

Anver

|

New

Grip and Rotate Modules Perform Two Operations in One

Compact Package New

Grip and Rotate Modules Perform Two Operations in One

Compact Package

Techno-Sommer Automatic is excited to announce the New

DGP404 Series Parallel Grip and Rotate Modules with

T-slot Guides, designed for high-load automation

applications that require parts to be sorted and rotated

90 or 180 degrees. This unique combination of parallel

gripper and rotator fits in tight spaces easily, while

the stable T-slot guides aid the absorption of large

force and moments.

"With up to 4 mm stroke per jaw, 350 N of grip force and

0.5 Nm of torque for rotation, the DGP packs a large

force in a compact design," said Sales Manager Costas

Charalambous. "This in turn allows engineers increased

flexibility with their application designs that will

save both time and space."

The DGP404 Series has separate pneumatic connections for

grip and rotate cylinders, so the grip function can

operate independently from the rotate function. Offered

in six different models for inside and outside gripping,

each unit can be set for either 90 or 180 degrees of

rotation and has magnetic position sensor slots built

into the housing. These models are also available with

mechanical gripping-force retention.

For more information about the New DGP404 Series

Parallel Grip and Rotate Modules with T-slot Guides from

Techno-Sommer Automatic, visit the Techno Web site at:

www.techno-sommer.com or call 800-819-3366 to speak to

an Application Engineer.

Contact

Techno

|

New

VRX rotary vane actuators from Tolomatic deliver high

torque, withstand high axial loads New

VRX rotary vane actuators from Tolomatic deliver high

torque, withstand high axial loads

MINNEAPOLIS � New VRX rotary vane actuators from

Tolomatic deliver up to 484 inch-pounds (54.7

Newton-meters) of torque at 100 psi (6.9 Bar) and can

withstand high axial loads of up to 23 pounds (102

Newtons). These pneumatically operated rotary vane

actuators are designed for use in material handling,

part feeding and clamping, pick and place operations,

cutting and many other industrial automation

applications requiring rotary motion.

“With larger vanes than other actuators in their size

class, the new VRX rotary vane actuators give design

engineers a very economical and powerful solution for

rotary actuation up to 280 degrees,� says Wyatt Grunerud,

a mechanical engineer with Tolomatic. “Featuring

Tolomatic’s exclusive Endurance TechnologySM for long

life, VRX actuators combine power and versatility with

high

axial and radial load capabilities not found in other

rotary actuators.�

VRX actuators are available in bore sizes of 1 inch

(25.4 mm), 1.75 inches (44.45 mm) and 2.5 inches (63.5

mm). Each model is available with single or double vanes

on a corrosion-resistant single- or double-ended shaft.

The single-vane models rotate to 280 degrees and produce

up to 242 inch-pounds (27.3 Newton-meters) of torque.

The double-vane models rotate to 100 degrees and produce

up to 484 inch-pounds (54.7 Newton-meters) of torque.

The VRX series also features self-lubricating Highly

Saturated Nitrile (HSN) seals that deliver three to five

times the service life of Buna-N. In addition, the seals

are molded directly onto the oversized vanes and rotor

shaft to ensure a tight fit. All models have

corrosion-resistant bodies and heads that are anodized

to ensure long life and low breakaway. VRX models with

double-ended shafts and bores of 1.75 inches (44.45 mm)

or 2.5 inches (63.5 mm) are available with an infinitely

adjustable stop option. This mechanism allows users to

dial in rotational stops of less than the 100 or 280

degrees of standard rotation.

For more than 50 years, Tolomatic has been a leading

supplier of electric linear actuators, pneumatic

actuators and power transmission products for factory

automation. Its extensive product line also includes

servo-driven high-thrust actuators, servo and stepper

motors, stepper drives and configured linear-motion

systems. Tolomatic’s electric linear and pneumatic

actuators are used in a variety of industries, including

the packaging, material handling, medical, food

processing, automotive, semiconductor and general

automation industries. For more information about VRX

rotary vane actuators, contact: Mona Rauen, marketing

communications manager, Tolomatic, 3800 County Road 116,

Hamel, MN. Phone: 763-478-4372; fax 763-478-4309. Web

site:

Tolomatic

|

Spartan

Scientific Series 3510 Valve Offers Value and

Versatility Spartan

Scientific Series 3510 Valve Offers Value and

Versatility

The competitively priced Spartan Scientific Series 3510

2-way, 2-position normally open or normally closed

solenoid/air pilot valve uses the latest materials,

providing the user with the highest quality, smallest

size per Cv of flow. It is ideal for air control, inert

gas control, water, condensate drainage, hot water

plumbing and sprinkler systems. The 3510 has an ambient

temperature range of -10� to +50°C and a pressure range

of 0-150 psi. Available in ¼”, 3/8� and ½” NPT sizes,

the polymer body section features a stainless steel

anti-flex ring for port strength. The molded pilot

section features high life cycle solenoid parts, a push,

non-locking manual override, and either quick connect

DIN 43650 “A� or “flying lead� electrical connection

options.

The Spartan Scientific Series 3510 is manufactured in

the USA to ISO 9001 with design specifications to the

highest quality standards. Complete specifications and

options can be found at www.spartanscientific.com or by

calling Bob Howard at 330-758-8446 x 122.

Spartan Scientific

P O Box 9792

Boardman, OH 44513

Tel: (330) 758-8446

Fax: (330) 758-3314

|

New

Modular Ejector System from Rexroth New

Modular Ejector System from Rexroth

New vacuum generator program from Rexroth is making

waves in the pneumatics sector. Compact and small basic

and inline ejectors in the newly designed EBS vacuum

generator series complete the Rexroth pneumatics

spectrum.

The three new versions in the EBS series � the EBS-PT

compact basic ejector, the small EBS-PI inline ejector,

and the electrically-operated EBS-ET � are optimized for

various applications. All types work according to the

Venturi principle for single-stage vacuum ejectors and

generate a strong vacuum while allowing a simultaneous

high vacuum flow capacity. All EBS ejectors are real

light-weights that can be integrated quickly and

flexibly.

The ejectors are wear and maintenance-free, since they

contain no moving parts. Fine-tuned performance levels

enable optimal adjustment to the requirements, making it

possible to attain maximum efficiency. Thanks to their

low weight, the ejectors can be mounted close to the

suction cups, enabling short evacuation times and

reducing air consumption to a minimum.

EBS-PT, EBS-ET and EBS-PI are all ideally suited for use

in the electronics and packaging industries, as well as

other automation applications. The larger EBS-PT version

is particularly suitable for sectors such as the

automotive industry, paper industry, wood working

industry, or sheet metal processing industry, whereas

the smaller EBS-PI has been optimized for handling

tasks.

The Rexroth EBS-PT/ET series are available in 6

performance levels with either a push-in fitting or

thread connection (ISO-G BSPP or NPTF). Thanks to all

these features, they provide numerous integration

options for the most varied applications. Vacuum

generator mounting can be done either directly via bolt

holes in the housing or flexibly by mounting it on a

clip-on strip. The latter option enables quick and easy

modular assembly of various ejector sizes on one strip.

The Rexroth EBS-PI is the simplest of the new vacuum

generator series. This ejector is available in two

performance levels. The compressed air and vacuum

connections are oriented in a straight line, so the

ejector can be directly integrated in the hose line; the

exhaust is guided out via side openings. All this is

made possible by the special design of the EBS-PI.Company Information:

Bosch Rexroth Canada

Ontario, CANADA

www.boschrexroth.ca

info@boschrexroth.ca

|

PIAB’s

new P6040 provides a modular solution in a smart design PIAB’s

new P6040 provides a modular solution in a smart design

PIAB, a global leader in industrial vacuum technology,

introduces its P6040 pump range. Featuring patented

COAX� technology, the P6040 can reduce energy costs by

up to 25% or more compared to other methods of

generating vacuum. With flexible mounting options, an

extensive per¬formance range and optional control

functions, the P6040 is highly adaptable and well suited

for most industrial vacu¬um applications.

With its smart design, the P6040 offers low and powerful

suction in a small package due to COAX� technology. This

allows the pump to be mounted close to the

point-of-suction, resulting in smaller pump requirements

with lessened energy needs. A natural extension of

PIAB’s P6010 pumps, the P6040’s operating efficiency is

further optimized with inte-grated control options like

Energy Saving (ES), helping companies reduce carbon

footprint and improve conservation efforts.

Since COAX� technology puts energy to maximum use, it

results in reduced compressed air needs and low noise

levels for the P6040, providing a peaceful working

atmosphere. Further improving the environment, while

also protecting sensitive products from static charge,

is the pump’s blow function. As compressed air is

cooled, blow-out air is also cooled.

To ensure reliable separation, blow air is used for

dividing thin sheets of material like plastic film or

paper. The P6040 generates a strong flow for blow

function at low pressure. When compressed air expands

through the COAX� cartridge, intake vacuum flow is added

to the flow of the air. Thus, one normal liter of

compressed air results in as much as five liters of blow

air.

The modular P6040 features an anodized aluminum housing

to withstand even the most demanding environments.

Upgrading existing equipment for better performance is

simple, while using the P6040 on new machines ensures

trouble-free operation in the most economical way. With

no moving parts or heat generation, and virtually no

maintenance required, downtime and work stoppage are

drastically reduced.

For more information about PIAB vacuum solutions for a

diverse range of applications, visit www.piab.com

|

Quarter

Turn Actuator DFPB from FESTO Quarter

Turn Actuator DFPB from FESTO

Easy to Reverse, Robust, Economical

Great Diversity � the Best Match Maximum economy and

ideally matched to process valve thanks to the great

variety of sizes � double-acting in 10 sizes from 10 to

300 Nm, single-acting in 7 sizes from 20 to 150 Nm.

Quick and Easy Installation

For example with an end-position sensing attachment to

VDI/VDE3845, flexible adapter selection, horizontal

NAMUR valve mounting, 0� or 45� process valves and

replacement of wearing parts without special tools. And

no distortion of the main valve!

Highly Robust in Use

Designed for outstanding reliability and safety! Among

its features are resistance to saltwater thanks to

excellent corrosion protection, maintenance-free, easy

to clean, captive laser ID and pressure aided lip seal

as the working seal. Furthermore, the pressure relief

slot benefits both the actuator and the compressed air

network.

Multi-functional

Design highlight: simple reversing of the direction of

rotation by inverting the actuator (clockwise or

anti-clockwise closing). Single-acting actuators can be

changed back and forth between spring force closing and

spring force opening.

For more information:

www.festo.com/us/dfpb

|

Flexeel

DuraWhip from Coilhose Flexeel

DuraWhip from Coilhose

This tough polyurethane jackhammer whip hose in Coilhose

Pneumatics� new Extreme Construxion Accessories� line is

far more flexible than traditional rubber hoses and

outlasts them as well, saving the user money. This whip

hose features vibration-resistant swivel fittings which

prevent the hose from twisting, and steel spring bend

restrictors which provide a 180-degree bend radius with

no kinking. Designed to be used between the jackhammer

hose and the tool, the DuraWhip� is highly resistant to

abrasion, oils and greases. Available with universal

couplings or universal swivels in 6 or 10 ft length ½”

I.D. hose in Hi Viz Construxion Orange� color.

-

Coilhose Pneumatics

-

19 Kimberly Road

-

East Brunswick, NJ 08816

-

P: 732.390.8480

-

F: 732.390.9693

Visit Coilhose

|

Rexroth

Extends Its Family of AS Series Air Preparation Units

with AS5 Model Rexroth

Extends Its Family of AS Series Air Preparation Units

with AS5 Model

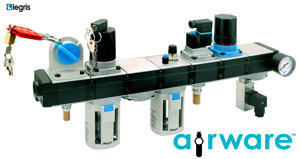

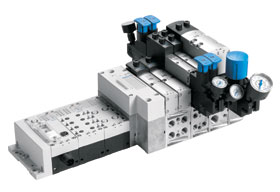

The Rexroth AS5 Series FRLs satisfy industry demands for

compressed air preparation. Along with the standard

functions of filtering, regulating, and lubricating,

this modular family of maintenance units feature air

connections up to one inch, allowing high flow capacity

for large-scale industrial applications.

With the AS5 series, Rexroth expands the AS family to

the high flow range. The AS5 regulator offers a flow of

up to 265 CFM (7500 l/min) with a width of only 3.3�.

The AS5 is available with 3/4� and 1� thread connections

in BSPP and NPTF forms. Series AS3 carries up to 159 CFM

(4500 l/min) with a module width of 2.5� and 3/8� or

1/2� thread connections. The most compact series, AS2,

with a width of 2� and 1/4� or 3/8� thread connections,

is suited for flows of up to 92 CFM (2600 l/min).

The family is generally characterized by ease of

maintenance. Large maintenance windows enable clear

viewing of the filter condensate levels and lubricator

fill levels. The filters can be optionally fitted with a

contamination display. Thanks to the easily accessible

bayonet catch, the reservoirs can be easily removed and

refastened as necessary.

The lubricators are available with an oil-level

indicator and Rexroth ST6 sensor for remote monitoring.

The patented oil filling system permits push-button

filling of the lubricators.

The Rexroth Air Service system impresses with its

modern, prizewinning industrial design. The AS2 series

has already received the if-Product design award 2006,

and was also nominated for the German Design Award 2007.

The components� smooth surface is easy to clean, and the

compact layout combined with new materials makes the AS

family particularly lightweight � even the larger units

of the AS5 series. Each series is fully modular,

designed for functional flexibility, and customizable to

the user’s requirements. In addition, single components

can be removed from an assembled manifold even after

installation. Modifications and extensions are possible

at any time.

The Series AS family is suitable for use in all

industries. During engineering, special attention was

paid to meeting industry-specific requirements such as

locking capability, an automotive industry requirement.

For this reason, the AS family can be used in almost

every application where compressed air quality must be

closely controlled.

CAD data for all AS components and an online

configurator for factory supplied custom assemblies are

available from the Internet via our "Interactive

Designer".

Bosch Rexroth Canada is the Canadian partner company of

Bosch Rexroth AG, one of the world’s leading specialists

in the field of drive and control technologies. Under

the brand name of Rexroth the company supplies more than

500,000 customers with tailored solutions for driving,

controlling and moving machinery used in industrial and

factory automation as well as in mobile applications. As

The Drive & Control Company, Bosch Rexroth develops,

produces and sells components and systems in more than

80 countries. In 2007 Bosch Rexroth AG, part of the

Bosch Group, achieved sales of about 5.4 billion Euro

with approximately 33,000 employees.

Company Information:

Bosch Rexroth Canada

Ontario, CANADA

www.boschrexroth.ca

info@boschrexroth.ca

|

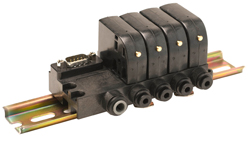

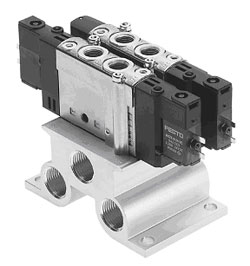

G3

Fieldbus Electronics from NUMATICS G3

Fieldbus Electronics from NUMATICS

The G3 Series product line is a completely modular

system. All of the G3 electronic modules plug together,

via mechanical clips, allowing easy assembly and field

changes. This makes the system highly distributable.

Additional flexibility is incorporated because the same

modules can be used in either centralized or distributed

applications. G3 electronics interfaces with Numatics

generation 2000 Series, ISO 5599/2 and ISO 15407-2

Series valve lines.

Contact Numatics

|

Compact

Valve Offers High Flow and Preferred Connectivity Compact

Valve Offers High Flow and Preferred Connectivity

The Pneumatics Division of Parker Hannifin announces the

release of its new Isys Micro Valve, a compact valve

manifold offering high flow and Preferred Connectivity

to Rockwell LogixTM Architecture. Parker designed the

Isys Micro using an innovative back-to-back valve

mounting style with a 42mm wide manifold that holds 4

valves and offers a 0.35 Cv flow.

For easy installation, Parker sells the Isys Micro

complete with all valves, fittings and mufflers. The

valve is also Fieldbus ready, making it ideal for

centralized or decentralized applications in markets

such as packaging, process control, alternative energy

systems, semiconductor, automated assembly, dairy

systems, fixturing systems, and water treatment systems.

“This Isys Micro valve design offers functionality for a

range of machine configurations,� explains Chris Landis,

Product Sales Manager, Pneumatics Division, Parker

Hannifin. “The flexibility of this valve means companies

can use 25 Pin D-sub connections for smaller machines or

employ simple node connections for larger machines using

fieldbus. It also means full Isysnet Fieldbus

functionality is available for large, complex machines

that use valves, inputs, and outputs. With Isysnet

Fieldbus, Isys Micro can provide full 256 input and 256

output capacity. It can handle up to 4 Valve Driver

modules, controlling 32 valves each, coupled to a single

fieldbus node.

“Best of all, our partnership with Rockwell Automation

allows us to offer this fieldbus solution with Preferred

Connectivity to the Rockwell Automation LogixTM

Architecture. Parker can provide all the information

needed for the device profile pre-loaded into the Allen

Bradley RSLogix5000TM software, reducing configuration

time by up to 70%. By eliminating data entry error and