|

PACKEX Toronto 2009 confirms its status of a Canadian must attend

event for all packaging and supply chain professionals

TORONTO, May 14, 2009 � The 34th edition of PACKEX Toronto which ended

on May 7th,

2009 was a huge success. In spite of difficult economic times, both

exhibitors and visitors

communicated positive feedback with comments focusing on the quality of

PACKEX

Toronto as an essential show for the Canadian industry.

Canada’s largest industrial trade show for the packaging, material

handling & logistics

industries, PACKEX Toronto welcomed over 354 exhibitors from Canada, the

United States,

and overseas. This edition presented a wider selection of exhibits

represented by 143 new

companies. Furthermore, PACKEX Toronto was co-located for the first time

ever with IPA

Canada, the National Food Process Exhibition. These two co-located

events provided

technologies and solutions under one roof, from food production to its

shipment.

PACKEX Toronto 2009 welcomed 7,034 attendees, showing a thriving 17%

increase from

the previous edition. The show has drawn visitors from major Canadian

provinces

including, Ontario, Quebec and Alberta

Bringing forward new sectors and new trends

The show presented for the first time in this 2009 edition, a new sector

based layout to

give exhibitors an equal opportunity to connect with buyers. This layout

featured; material

handling, packaging machinery & machinery components, materials,

converting, pre-press

& printing and food processing with IPA Canada.

Keeping industry professionals on top of new market challenges and

trends

This edition’s conference program marked a huge success, with a

remarkable quality of

speakers, featuring presentations with three main topics: Youth and

Trends,

Sustainability and Safety, Security and Traceability. PACKEX Toronto was

also host to

the Wal-Mart conference on “Sustainable Strategies� organized in

partnership with the

Packaging Association of Canada.

This 2009 edition marks an important success for PACKEX Toronto as well

as for IPA

Canada, the new brand for the National Food Process Exhibition. PACKEX

Toronto wishes to

thank the Packaging Association of Canada as well as all our other

partners, exhibitors and

visitors who contributed to the success of this biennial event

About PACKEX Toronto

PACKEX Toronto is Canada’s national packaging, food process, material

handling &

logistics exhibition. With a 50-year plus legacy of success, the show

ranks among

Canada’s largest industrial trade exhibitions drawing visitors and

exhibitors from

across North America, Europe and Asia. Operated by PAC-Exhibition Inc.,

the show

is jointly owned by Comexposium and the Packaging Association of Canada.

Looking forward to see you at PACKEX Toronto / IPA Canada 2011! For more

information visit

www.PACKEXtoronto.com

Bionic solutions for efficient

automation of the future Inspired by nature

Maximum performance with minimum energy consumption: Nature

shows the way to energy-efficient movement processes in

tomorrow’s production and provides impulses for astounding new

practical applications.

Flexibility, lightness in relation to the mass to be displaced

and energy efficiency are acquiring increasing significance in

automation. With highly diverse examples, nature demonstrates

how maximum performance can be achieved with minimum consumption

of energy.

Dr. Eberhard Veit, Chairman of the Management Board and Director

of Technology and Market Positioning at Festo AG, explains: “We

are using bionics to sound out new technologies and to offer our

customers even more efficient solutions in automation.�

Over the past few years, the Festo Bionic Learning Network � a

cooperation of Festo with renowned universities, institutes and

development companies � has become established as an integral

part of Festo’s innovation processes.

The Bionic Learning Network thus reflects Festo’s solutions

competence for evaluating new approaches in sustainable product

development. “We intend to be the innovation leader in our

sector. To this end, we must repeatedly travel down new, in

other words entirely different, paths in order to provide our

customers with added value,� says Dr. Veit.

Bionic design principles serve as the basis for the development

of new gripper technology for flexible adaptive gripping in the

mechanical handling industry.

In biomechatronics, Festo is investigating new approaches in the

control and regulation of autonomous bionic systems, all the way

up to smart system integration and the application of

state-of-the-art communication technologies. Autonomous,

versatile, adaptive and self-regulating processes will acquire

increasing significance in the future for the automation of

production. In this process, the ongoing development of sensor

and regulating technologies along the road to decentralised,

autonomous, self-controlling and self-organising systems is

benefiting from inspiration provided by nature.

Festo

Herkules�

Lift Systems Are Utilized by NASA for the Ares I-X Constellation

Program Herkules�

Lift Systems Are Utilized by NASA for the Ares I-X Constellation

Program

Walled Lake, Michigan. Herkules Equipment Corporation worked

closely with United Space Alliance (USA) for the upcoming Ares

I-X mission by customizing a lift system that enabled rocket

engineers to securely load 2400 pound parachutes into a booster

rocket. Herkules� engineering team designed the lift system to

meet all of USA’s unique specifications including raised height,

travel, foot print, portability and all strict NASA safety

standards with a 3 times safety factor. The lifts are currently

used at the Kennedy Space Center in Cape Canaveral, Florida.

The purpose of the three lift systems is to accurately raise the

3 large “rocket sized� parachutes independently to meet the top

section of the booster rocket. The parachutes are then packed

correctly and ultimately deployed in the first stage separation

+123 seconds after lift-off. Fork pockets allow the lift to be

moved when and where it is needed. The small footprint, combined

with the required high raised height, created unique safety

challenges that were answered in the design process to USA’s

satisfaction, guided by strict regulations.

“It was great to see things come together as planned! Thank you

again for all the support� wrote the USA Ares 1st Stage GSE IPT

Lead.

Herkules� pneumatic lift systems are virtually maintenance-free,

with no messy fluids or costly cylinders to replace. The power

source, Herkules� Air Bag� technology, provides a patented

direct one-to-one lift ratio, eliminating stress on the

scissors, minimizing wear and maintenance. The lifting motion is

smooth and stable. The heavy-duty air bags are built for rugged

daily use giving facilities a lifetime of trouble-free

operation.

Herkules Equipment Corporation has been manufacturing Pneumatic

Lifting Equipment for over 20 years, including (standard and

custom); Lift Tables, Lift & Rotates, Lift & Tilts, Human Lifts,

Power Rotate Systems, Lifts for Integration, Cart Positioners,

Pallet Positioners, and Vehicle Lifts.

For more product information, contact Herkules at 800-444-4351,

or email info@herkules.us. Visit our website at

www.herkules.us

New

catalog SC-600 titled “Electro-Pneumatic Devices� covers five E/P valves

series, E/P positioners and electronic flowmeters. New

catalog SC-600 titled “Electro-Pneumatic Devices� covers five E/P valves

series, E/P positioners and electronic flowmeters.

The new Rexroth fifty-six page catalog SC-600 provides technical

information, drawings and ordering information on electro-pneumatic

proportional control valves, positioners and electronic flowmeters. The

catalog covers the following E/P valve series: ED02 proportional

solenoid-analog control; EV04 pilot control; ED05 proportional

solenoid-analog link, analog control, VDS link and DDL link; ED07

proportional solenoid-analog control, VDS link, DDL link and Profibus-DP;

and ED12 proportional solenoid-analog control. The valves feature flows

from 3.53 SCFM to 91.8 SCFM. An overview chart in the inside front cover

compares technical features, electrical data and safety features of the

valve series. Rexroth E/P’s are known for their precision and low

hysteresis characteristics. Bus protocols supported include:

Ethernet/IP, EtherCAT, ControlNet, DeviceNet, INTERBUS-S, MODBUS TCP,

Profibus-DP, CANopen and TCP/IP.

Company Information:

Bosch Rexroth Canada

Ontario, CANADA

www.boschrexroth.ca

info@boschrexroth.ca

Promotion

of Ron Wright Promotion

of Ron Wright

SCHUNK, a world leader in Automation, Workholding and Toolholding

Technology, is pleased to announce the promotion of Ron Wright to

General Manager of SCHUNK Intec. Canada. SCHUNK Canada opened its doors

in 2006 and has experienced exceptional growth. “Mr. Wright is the right

person for the job to take SCHUNK Canada to the next level� Said Mr.

Guerry VP of Sales for SCHUNK North America.

Mr. Wright has been with SCHUNK USA for 7 years, most recently as the

National Sales Manager for Toolholding and Workholding. As the General

Manager Mr. Wright will be responsible for all aspects of the Canadian

operation which includes Automation as well as Toolholding and

Workholding. Mr. Wright “… I look forward to the opportunity that the

new position provides as well as to work with the great staff in our

Canadian office.�

SCHUNK Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560

Phone: 919.572.2705 or

800.772.4865

Fax: 919.572.2818

www.schunk.com

info@us.schunk.com

Rexroth confirms commitment to developing and executing environmental management standards for today and tomorrow

Bosch Rexroth Canada (BRCA), a leading supplier for industrial, mobile and automation applications, announced that its Welland, Ontario facility recently received ISO 14001:2004 registration.

The ISO registration signifies that BRCA has committed to conform and comply with the ISO 14001:2004 standards as well as the applicable environmental legislation and regulations required. The registration also indicates that BRCA has developed a plan for continually improving its environmental performance well into the future.

“Obtaining an ISO 14001:2004 registration shows our customers that we hold ourselves to the highest environmental standards in the world,� said Boyd de Waard, president of BRCA. “We examined our environmental system closely and developed a plan that met each of ISO’s benchmarks. As a result, we’re confident that we’re environmentally compliant on the local, regional, national and international levels,� he said.

The company assigned resources as needed to satisfy the ISO requirements. Achieving the ISO 14001:2004 registration required that Bosch Rexroth Canada deploy a team to develop an implementation plan and participate in an environmental compliance audit monitored by a capable third party overseer. The entire process included completion of internal audits and a stage-one third party “readiness� audit prior to the registration audit.

Marco Gervasio, project manager for the Bosch Rexroth implementation, stated that while principal organizations in Europe and developed areas of Asia tend to be more aggressive in obtaining ISO 14001:2004 registration, North America is now coming on board as well.

“Bosch Rexroth Canada is one of about 3,000 Canadian companies that have received this registration,� said Gervasio. “That number is relatively low considering the number of companies and notable organizations operating nationwide. Bosch Rexroth has made this registration mandatory for all its sites globally. Being good stewards of the environment is a responsibility the company takes seriously,� he said.

Bosch Rexroth Canada is the Canadian partner company of Bosch Rexroth AG, one of the world’s leading specialists in the field of drive and control technologies. Under the brand name of Rexroth the company supplies more than 500,000 customers with tailored solutions for driving, controlling and moving machinery used in industrial and factory automation as well as in mobile applications. As The Drive & Control Company, Bosch Rexroth develops, produces and sells components and systems in more than 80 countries. In 2007 Bosch Rexroth AG, part of the Bosch Group, achieved sales of about 5.4 billion Euro with approximately 33,000 employees.

Company Information:

Bosch Rexroth Canada

Ontario, CANADA

www.boschrexroth.ca

info@boschrexroth.ca

Dr. Albert Hieronimus to be new chairman of the Bosch Rexroth AG board of management Dr. Albert Hieronimus to be new chairman of the Bosch Rexroth AG board of management

Dr. Karl Tragl appointed to board of management

Manfred Grundke leaving Bosch to take up post as managing director of

a privately owned German company

V K Viswanathan to be new managing director of the Bosch Indian

subsidiary Motor Industries Company Limited (Mico)

Stuttgart/Lohr. Effective February 1, 2008, Dr. Albert Hieronimus (60) is to be

the new chairman of the Bosch Rexroth AG board of management. Hieronimus

is currently managing director of Motor Industries Company Limited (Mico), the

Bosch Indian subsidiary headquartered in Bangalore. At the same time, Dr. Karl

Tragl (45), who is responsible for Bosch Rexroth’s Electric Drives and Controls

division, will be appointed to the company’s board of management. In his new

role, he will be responsible for sales, a task currently carried out by Bosch

Rexroth AG board of management chairman Manfred Grundke (52) in addition

to his other duties. Manfred Grundke is leaving Bosch on February 29, 2008, to

take up a post as managing director of a privately owned German company “We

would like to thank Manfred Grundke for his successful work of the past years,

and are glad to welcome Dr. Albert Hieronimus as his successor, since he knows

Bosch Rexroth very well,� said Dr. Siegfried Dais, deputy chairman of the

Bosch board of management and chairman of the Bosch Rexroth AG

supervisory council.

Following his mathematics degree, and while studying for his doctorate,

Dr. Albert Hieronimus first worked as a research assistant at the University of

Cologne before joining what was then Mannesmann AG in 1979. He held

various posts there, with increasing levels of responsibility. In 1993, he was

appointed to the board of management of Mannesmann Rexroth AG. Following

the merger of Mannesmann Rexroth AG with the Bosch Automation technology

division in 2001, he initially served on the executive management of Bosch

Rexroth, where he was responsible for human resources, IT, and coordinating

post-merger integration. In 2003, he left Bosch Rexroth to become managing

director of Mico, Bosch’s Indian subsidiary. Effective February 1, 2008, this

post will pass to V K Viswanathan, currently a member of the Mico

management team with responsibility for several Bosch divisions. Hieronimus

will retain his links with India, becoming chairman of the Indian company’s

board of directors effective February 1, 2008. Hieronimus is married and has

two grown-up children.

A physics graduate, Dr. Karl Tragl joined Mannesmann Rexroth in 2000,

following several positions at the German Aerospace Research Center and Siemens

with assignments in Munich and the UK. He is currently president of the division

Electric Drives and Controls of Bosch Rexroth, with responsibility for

technology. Tragl is married and has four children.

Automation secures jobs

If you are looking for innovations, come to Germany:

Again in 2008 inventors from all over the world will be converging on AUTOMATICA

Six months before AUTOMATICA 2008 gets under way the robotics and automation sector is riding high. No sign of any slowdown here. The order books have been full for months, employees and machinery are working at full stretch. A happy situation, but one which requires clever juggling of impatient clients and ever tighter capacities. At the same time managers have to be looking to the future. In the past when order volumes were high, attention focused exclusively on ongoing production. This time the manufacturers of robot and assembly systems are reporting that despite full order books, they are investing in parallel in projects for the future.

On virtually every street corner we get a sense that things are looking up in the economy. The figures also back up this impression: the

IFR, International Federation of Robotics, for example, reported that robotics manufacturers worldwide achieved sales of around 5.8 billion US dollars in the last year. If systems integrators are included, then the total rises to 17 billion, even despite the fact that the automotive and electronic engineering industries significantly reduced their investment in robotics during the same period. IFR Chairman Stefan Müller explains: “All other industries are nevertheless investing in robotics like never before.�

Next year, too, sector experts are expecting that most growth will come from general industry (all sectors of industry except the automotive sector). These sectors have some catching up to do. Although they generally do have largely automated processes, in contrast to the car industry, those processes are often very rigid. With a customer base concerned more or less with individuality, the production equipment has to be flexible. Typical of this development is the packaging sector: For years the use of robots, i.e. the flexible part of automation, was restricted to pallet operations, but now this industry is a shining example of how to use the many forms of automation.

Yet this trend does have its critics: machines instead of people � again and again the manufacturers of robots and automation are accused of destroying jobs. In fact the very opposite can be true, as shown by many German machinery and plant manufacturers. Companies with sophisticated automated systems and perfectly coordinated processes are not only expanding their production on the world market, they are even bringing back production capacities that were located abroad. Companies reporting this kind of trend include not only the top automotive suppliers but also construction machinery manufacturers like Bomag of Boppard and Vögele of Mannheim.

Innovation � and this is no secret � is possibly the only chance for German machinery manufacturers to hold out against the ever improving competition from abroad. A trade fair like

AUTOMATICA, with its high proportion of international exhibitors and visitors, is ideal for getting to know and evaluating the competition. The visitors from all over the world have high expectations of German inventions and developments � and they will certainly not be disappointed:

In assembly the new trends are called ‘Desktop Factory� (Bosch und

Rohwedder) and ‘Tabletop Automation� (Stäubli). Such units are highly versatile production platforms. The individual compact segments can be fitted with a range of different production equipment and put together in a series. For ever shorter product life-cycles it is possible to create specifically equipped and efficient production and assembly lines. Most of the elements in such a line can then be used later for other production operations.

In robotics an agile multi-arm technology with a sophisticated vision system is one of the most sought-after technologies. But older concepts, too, such as delta kinematics are being revived and competing with current standards. Kinematics is already very fast, but with four instead of three arms the robots turn into really high speed operatives. Manufacturers of bent-arm robots are responding to this development by producing robots that have two drives per axis and which can also move at ultra high speed.

There is certainly no lack of exciting ideas and concepts � just when and how these concepts are implemented in market-ready solutions will be another interesting aspect to find out about at AUTOMATICA 2008.

For further information on AUTOMATICA 2008, go to:

www.automatica-munich.com.

Press contact for AUTOMATICA

Dr Jutta Seitz

Head of Marketing & Communication

Capital and Consumer Goods Fairs

Tel. (+49 89) 949-20680

Fax (+49 89) 949-97 20680

e-mail: jutta.seitz@messe-muenchen.de

AMETEK FORMS ULTRA PRECISION TECHNOLOGIES DIVISION

New Division Combines Taylor Hobson, Solatron Metrology and Precitech

Paoli, PA,–AMETEK Inc. has formed a new Ultra Precision Technologies Division that brings together its Taylor Hobson Division with two more recently acquired businesses: Solartron Metrology and

Precitech.

“All three businesses—Taylor Hobson, Solartron Metrology and Precitech—have strong organizations, enjoy excellent industry reputations and serve a growing global customer base,� notes Bruce Wilson, Vice President and General Manager of AMETEK Ultra Precision Technologies.

“Together, they allow AMETEK to leverage combined manufacturing operations, technological capabilities and distribution competencies to provide our customers with the broadest range and most advanced metrology and ultra precise manufacturing products available today,� he added.

Taylor Hobson, based in Leicester, England, is an acknowledged leader in ultra-precision measurement instrumentation and a pioneer in the development of instruments for metrology and nanotechnology. Acquired in 2004, Taylor Hobson represented AMETEK’s initial entry into ultra-precision manufacturing and nanotechnology.

AMETEK added to its position in 2005 with the acquisition of Solartron Metrology, a well-established leader in digital and analog instruments used in the precision measurement of machined and fabricated parts that is also based in the United Kingdom. In late 2006, AMETEK acquired

Precitech, a leading U.S. manufacturer of ultra-precision machining systems for a variety of markets, including nanotechnology, military, defense and ophthalmic.

AMETEK Ultra Precision Technologies is headquartered in Leicester, England, with manufacturing operations in Bognor Regis, England; and Keene, New Hampshire and a global network of sales and service locations.

Advanced Mechatronics Training Equipment Grand Opening � Advanced Mechatronics Training Equipment Grand Opening �

Suffolk County Community College Brentwood, New York

The need for advanced technical education is a popular subject these days, and it is one that must be addressed immediately.

In order to keep a competitive edge, manufacturing companies are upgrading their automation equipment to increase productivity and enable the production of high quality products. The automated equipment that is used today requires technicians with a new set of technical skills to operate and maintain them.

The US Department of Labor estimates that more than 10 million skilled factory jobs will be unfilled by the year 2020 � only 13 years from now! It is essential that high-tech, specialized training be made available to students and to the current workforce.

Suffolk County Community College, Brentwood, New York, in partnership with Festo Corporation recently unveiled the new Advanced Mechatronics Training Center. The new center unveiled advanced, high-tech manufacturing and process control equipment which reflects world-class training capabilities. The hope is to create greater awareness among students, school systems, industry leaders, workforce development agencies, economic development agencies and government officials about the variety of career paths that exist in the manufacturing field.

As part of this mission to provide affordable higher education and workforce development opportunities, SCCC applied for and received a three-year $2.4 million federal grant through the United States Department of Labor Employment & Training Administration to train workers for advanced manufacturing. This resulted in a new curriculum � Mechatronics � that will give the manufacturing workforce more highly developed skills increasing their employment opportunities and salary levels.

More than 200 workers from more than 38 manufacturing companies have enrolled in the college’s mechatronics certificate program since last spring. The college also plans to offer an associate degree program in the field next fall.

As a global manufacturer of high technology, factory automation systems, Festo Corporation is committed to working with other community colleges throughout the United States to establish training centers to keep up with the technology.

For additional information, please contact Learning System Division of Festo Corporation.

Main Office: (631) 404-3182

Technical Support: (631) 404-3184

Email: petra.milks@us.festo.com

KEPNER PRODUCTS COMPANY � 60 YEARS OF EXCELLENCE

Since 1948, Kepner Products Company has pioneered design, development and manufacture of precision pressure and flow control valves featuring the Kepner Flexible Seal Seat.

The Flexible Seal Seat is central to all our products and is a carefully engineered combination of metal-to-metal and resilient elastomer sealing. Kepner valves offer dependable zero leakage in a broad variety of industries for many different gas and liquid media applications. Valve functions include high durability check, relief, shuttle and pilot operated controls.

Inline and cavity insert cartridge designs offer broad ranging choices in sizes, port configurations, construction materials, pressures and flows. Both poppet and ball control elements are available.

Precision manufacturing procedures provide design flexibility, efficient production and enhanced quality products. We pride ourselves in our responsiveness to individual customer problems. Successes include both standard zero leak design solutions and a multitude of customized designs for both fluid power and fluid transfer applications.

Ongoing research and development activities at Kepner are advancing our technical capabilities. Every valve continues to receive individual attention in assembly, testing and custom reporting ensuring proper operation and sufficient documentation.

With an excellent product and a focus on quality and responsiveness, we strive to process orders quickly and correctly. Customer service drives us to continue to improve as demands for Kepner valves in the marketplace continue to grow.

Kepner Products Company

630-279-1550 Fax: 630-279-9669 Website: www.kepner.com

CLIPPARD MINIATURE PNEUMATICS

FOR SCIENTIFIC APPLICATIONS CLIPPARD MINIATURE PNEUMATICS

FOR SCIENTIFIC APPLICATIONS

Clippard Instrument Laboratory, Inc., manufacturer of the industry’s most complete line of miniature fluid power products, has just released an all-new catalog for Scientific applications such as medical, pharmaceutical, analytical, dental and more.

Products include Electronic Valves, Check Valves, Control Valves, Proportional Valves, Regulators, Fittings and Tubing and more. Also being introduced in this literature is the all new series of Electronic Valves developed for use in Oxygen-enriched environments for applications that are extremely sensitive to contamination.

Contact Clippard today, or your local distributor, for your FREE catalog today.

Clippard Instrument Laboratory, Inc.

739) Colerain Avenue

Cincinnati, Ohio 45239

513-521-4261 � 877-245-6247

www.clippard.com/catalog-pol

COVAL Vacuum Manager opens North American subsidiary. COVAL Vacuum Manager opens North American subsidiary.

Coval Vacuum Technology Inc., a subsidiary of Coval Vacuum Managers is now operational in the US.

Coval Vacuum Technology Inc., the Raleigh, NC based subsidiary for Coval Vacuum Managers was established in July of 2007. Coval Vacuum Technology Inc. will support the North American market. The company will offer local inventory and will provide sales and technical support through an expanding dealer network.

COVAL specializes in the manufacturing and distribution of vacuum components for automation with a worldwide focus in the packaging, plastics, and automotive industries. Coval has been a manufacturer of vacuum components (suction cups, vacuum pumps

(venturi/electrical), vacuum switches, spring compensators, peripheral devices) for more than 20 years and is a force for innovation in the field of automation technology.

Coval assists their customers in optimizing the performance of automated production equipment, as it relates to vacuum. Due to innovative components and complete diagnostics of the vacuum circuit, Coval can provide reliable solutions to significantly reduce energy consumption and noise level while improving productivity. For more information about Coval please visit the website at

www.coval.com.

-

Your contact @ Coval Inc.

-

Matt Ossi

-

Technical Sales Manager

-

Matt.ossi@coval.com

|

-

Coval Inc.

-

212-112 Powell Drive

-

Raleigh, NC 27606

-

www.coval.com

|

SCHUNK announces the acquisition of GEMOTEC SCHUNK announces the acquisition of GEMOTEC

SCHUNK is expanding its extensive Automation Component line with the acquisition of Gemotec Montagetechnik GmbH.

Gemotec manufacturers a complete product range of modular assembly technology, consisting of pneumatically and electrically operated linear units, gripper modules and rotary actuators. The Gemotec components are proven in thousands of assembly applications and very well known throughout Europe. These highly dynamic and flexible assembly solutions will easily adapt most to any assembly automation needs without special adapter plate designs. Design time is saved and costs are reduced.

The comprehensive product line is completely modular, and can be freely integrated with other components of the system. It’s easy “combine instead of design�, individual assembly solutions right through to complete functional assemblies, with the use of an intuitive sizing software and without having to resort to special adapter plates or designs.

For SCHUNK the acquisition of Gemotec represents the perfect complement to the existing product range, from which SCHUNK hopes to achieve considerable synergies and significantly improve market coverage. Customers can now obtain an extended range of products and take advantage of the worldwide sales and support network of SCHUNK.

SCHUNK Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560

Phone: 919.572.2705 or

800.772.4865

Fax: 919.572.2818

www.schunk.com

info@us.schunk.com

Air Cylinders Direct is proud to announce the unveiling of our new, more comprehensive e-commerce site. Air Cylinders Direct is proud to announce the unveiling of our new, more comprehensive e-commerce site.

The site now includes a complete line of air cylinders that range from a robust NFPA Interchangeable product line to an economical non-repairable series. You can now purchase additional pneumatic components at www.AirCylindersDirect.com. These component types included Motion Control, Directional Control Valves, Air Preparation, Composite Fittings, and Composite Flow Control products.

The Motion Control product offering includes pneumatic slides, grippers, swing clamps, and air bellows. Our Directional Control Valve line now includes a multitude of mechanically operated button valves, i.e., palm button, palm/reset, push button, roller/limit, toggle, and turn button. Air Preparation products consist of air filters, regulators, filter/regulator combo units, and shut off valves. Air Cylinders Direct Fittings and Accessories section now includes a complete line of both in-line and in-port flow controls as well as a full line of composite fittings.

In addition to all the new product lines, we are pleased to offer the most advanced support tools in the pneumatic component industry. These tools include 3D CAD models for all Motion Control products. Our dynamic 3D CAD configuration program only requires you to provide your application requirement; we take care of the rest! Subsequently, the desired CAD model is quickly generated and can be retrieved via e-mail. This includes both 2D drawings as well as 3D models in all of the popular formats. In fact, the models are available in over 65 different native CAD formats. In addition to our advanced dynamic 3D CAD configuration program, you will find automated application calculators that will quickly and easily calculate required cylinder bore sizes, estimated cylinder extend and retract forces, and required air line pressure. This is just another example of why Air Cylinders Direct is The Online Answer to Air Applications.

1-866-404-5300 � telephone

sales@AirCylindersDirect.com

www.AirCylindersDirect.com

IFPE 2008 Will Be Largest Ever

Power Transmission Exposition Sets Exhibit Space Sales Record

The 2008 edition of the IFPE - International Exposition for Power Transmission will be the largest in the show’s history, with more than 115,000 net square feet of exhibit space already reserved (10,718 net square meters) with the show nine months away.

The last IFPE, held in 2005, was also a record-breaker, topping off at 111,471 net square feet of exhibits. IFPE 2008 will be held March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, USA.

The triennial show is the leading international exposition and technical conference dedicated to power transmission and motion control technologies. It is co-located with the

CONEXPO-CON/AGG 2008 exposition, which targets the construction industries. IFPE attendee registration permits access to both shows.

IFPE 2008 exhibitors include longtime participants as well as new-to-the-show companies, from smaller specialized firms to global leaders, and from the United States, Canada and worldwide.

The American Gear Manufacturers Association (AGMA) and the Power Transmission Distributors Association

(PTDA) are sponsoring IFPE 2008 exhibit pavilions, and there will be an exhibit pavilion which highlights the expanded presence of sensors suppliers at the show. IFPE 2008 will also feature several international exhibit pavilions, including China, Italy, Spain and Taiwan.

“Attendees will be able to examine the latest equipment and technologies to help solve their design challenges, whether they involve hydraulics, pneumatics, electrical or mechanical processes. And, they’ll be able to discuss new developments and cost-effective applications with the industry’s leading suppliers,� stated IFPE Show Manager Sara Truesdale Mooney.

IFPE is geared to engineers and others involved in the design and manufacturing process in a variety of industry segments, including off-road equipment, fluid power/power transmission products, electrical machinery, instruments/controls, distribution, material handling, manufacturing/production automation/machine tools, automotive/commercial vehicles, engineering services, defense/aerospace and amusement/entertainment technology.

IFPE is co-owned by the National Fluid Power Association (NFPA) along with the Association of Equipment Manufacturers

(AEM), National Ready Mixed Concrete Association (NRMCA) and National Stone, Sand & Gravel Association

(NSSGA).

Exhibit space is still available on a first come, first served basis. For more information on attending or exhibiting, phone +1-414-298-4141 or toll free North America +1-800-867-6060, fax +1-414-272-2672 or online at

www.ifpe.com.

IFPE 2008 and CONEXPO-CON/AGG 2008 Earn International Buyer Program Status from U.S. Government

Services Connect Global Buyers and Sellers

The CONEXPO-CON/AGG 2008 and co-located IFPE 2008 expositions have been selected by the U.S. Department of Commerce (DOC) to participate in its International Buyer Program (IBP). The IBP will help bring international attendees to the shows and facilitate at-show connections with exhibitors wanting to sell to the global marketplace.

Only a few expositions are named to the IBP each year based on their status as quality events serving industries with excellent export potential. Approximately 20 percent of show attendance to the co-located events is expected to come from outside the United States.

The IBP promotes selected trade shows to a worldwide audience through its Commercial Service International Posts and selected embassies and consulates. Key activities under the IBP are Commerce Department recruitment of official trade delegations to attend the shows and a “matchmaking� service to facilitate buyer-seller interaction and onsite export counseling.

As part of the IBP, CONEXPO-CON/AGG 2008 and IFPE 2008 will operate a comprehensive International Trade Center during the shows, with services to include interpreters, a separate registration area, message centers, phone/fax/e-mail access, meeting rooms and a lounge area. The shows will also provide assistance with travel and housing arrangements for international delegations.

The shows will produce an Export Opportunities Guide (print or electronic versions available) for distribution onsite and to Commerce Department international posts. The guide is designed to help attendees easily locate companies interested in doing business on a worldwide basis through export sales, agency relationships, distributor investment or joint ventures.

As part of the IBP agreement, CONEXPO-CON.AGG 2008 and IFPE 2008 in addition will offer show planning information and registration materials in several world languages via print brochures and on the shows� websites. Selected educational programming will also be offered with simultaneous interpretation into Spanish, Portuguese and Russian.

“The international attendance at CONEXPO-CON/AGG and IFPE illustrates the increasingly global scope of our industries, and the shows� reputation as a quality destination to conduct business. We’re pleased to have the continued support of the U.S. Commerce Department,� stated Petra Kaiser, director of international marketing for the shows.

For more information on attending or exhibiting, phone +1-414-298-4141 or toll free 800-867-6060, fax +1-414-272-2672 or online at www.conexpoconagg.com or

www.ifpe.com.

Registration and Housing Opens July 9, 2007 for IFPE 2008 and CONEXPO-CON/AGG 2008

Sign Up in Advance to Save Time and Money

Advance registration for the CONEXPO-CON/AGG 2008 and IFPE 2008 expositions is open as of July 9, 2007. Attendees will also be able to register in advance for the shows� many educational opportunities as well as obtain housing accommodations.

CONEXPO-CON/AGG and the co-located IFPE 2008 will be held March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, USA. The shows will be the international gathering place in 2008 for the construction and motion control industries.

One registration allows access to the exhibits of both shows, and advance registration saves money off the on-site fee.

Register online at www.conexpoconagg.com or www.ifpe.com, or via fax or mail. Advance registration closes February 8, 2008.

Full information on the show is available online, and attendees can also request a registration brochure with details and registration forms. Downloadable registration forms on the show websites will be available in several languages besides English, including Arabic, Chinese, French, German, Italian, Japanese, Korean, Portuguese, Russian and Spanish.

Advance registration also saves money for attendees taking advantage of

CONEXPO-CON/AGG 2008 education programming. Single tickets will be available as well as four-ticket and 12-ticket value packs.

IFPE 2008 will also offer extensive education. The IFPE Technical Conference is $75 pre-show and at-show, and includes a CD-ROM of the proceedings. The new IFPE Innovations and Solutions Showcase sessions are no charge to all registered IFPE and

CONEXPO-CON/AGG attendees.

For fax and mail registrations, fax numbers are +1-847-940-2386 or toll free North America (800) 521-6017, and mailing address is

CONEXPO-CON/AGG 2008 & IFPE 2008 Registration Headquarters c/o

Experient, 108 Wilmot Road - Suite 400, Deerfield, Illinois USA 60015-5124.

Gear Manufacturers to be Featured In New IFPE 2008 Exhibit Pavilion

American Gear Manufacturers Association Sponsors Pavilion for Members

The American Gear Manufacturers Association (AGMA) will sponsor an exhibit pavilion for its members at the 2008 IFPE - International Exposition for Power Transmission. AGMA will also promote the show as an IFPE 2008 supporting organization.

IFPE 2008 will be held March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, USA and will be North Americas largest exposition and technical conference for hydraulic, pneumatic, electrical and mechanical power transmission components, systems and controls.

AGMA members primarily manufacture gears, gearboxes, flexible couplings or mechanical power transmission equipment or components; supply machine tools, cutting tools and other capital equipment to the gear manufacturing industry; or offer supplies or services such as gear blanks, lubricants, heat-treating and grinding.

We welcome AGMAs participation in the show. Industry partnerships such as this strengthen IFPEs scope and are a key to its success, stated Linda Western, Executive Director of the National Fluid Power Association (NFPA), IFPEs co-owner.

Our members products and services are a good fit with IFPE and our exhibit pavilion at the show is one more way we can offer them exposure to potential customers, added Kurt

Medert, Vice President of AGMA.

IFPE 2008 is co-located with CONEXPO-CON/AGG 2008, which will be the largest international gathering place in 2008 for the construction industries. The shows are expected to attract more than 125,000 visitors from around the world. For more information on attending or exhibiting, phone 414-298-4141 or toll free 800-867-6060, fax 414-272-2672 or online at www.ifpe.com or

www.conexpoconagg.com.

IFPE 2008 Plans New Exhibits Pavilion To Spotlight Sensor Manufacturers

The 2008 IFPE - International Exposition for Power Transmission will feature a new product-specific exhibits pavilion that will highlight an expanded presence of sensor equipment manufacturers at the show.

Exhibitors in this pavilion will display sensors utilized for measuring acceleration, displacement, flow, fluid level, presence/proximity, pressure, temperature and velocity.

IFPE 2008 will be held March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, USA and will be North Americas largest exposition and technical conference for hydraulic, pneumatic, electrical and mechanical power transmission components, systems and controls.

This is a growing product segment at IFPE, and this pavilion is another example of the wide range of motion control products and technologies that attendees will find at the show, stated IFPE Show Manager Sara Truesdale Mooney.

IFPE 2008 is co-located with CONEXPO-CON/AGG 2008, which will be the largest international gathering place in 2008 for the construction industries. The shows are expected to attract more than 125,000 visitors from around the world.

In conjunction with the IFPE 2008 exhibition, the IFPE Technical Conference will be held and will focus on all areas of technology: research, design, new developments, materials and case histories. The conference will include a new electronic controls symposium in addition to its technology and design program.

For more information on attending or exhibiting, phone 414-298-4141 or toll free 800-867-6060, fax 414-272-2672 or online at www.ifpe.com or

www.conexpoconagg.com.

IFPE and CONEXPO-CON/AGG Expositions Extend Co-Location Partnership Through 2014

Next Shows Set for March 11-15, 2008 in Las Vegas, USA

The IFPE and CONEXPO-CON/AGG expositions have extended their co-location agreement through 2014 in recognition of the successful partnership between the two shows, which has benefited both exhibitors and attendees.

IFPE and CONEXPO-CON/AGG first co-located in 2002, and the next edition of the triennial shows will be March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, USA. An estimated 125,000 visitors are expected at the two events.

“We have been extremely pleased with the results of the co-location. Our exhibitors have access to a vast array of OEM customers at the adjacent

CONEXPO-CON/AGG exhibits, and our attendees have the opportunity to see a wide variety of quality, innovative solutions from more than 500 leading suppliers,� stated Linda Western, Executive Director of the National Fluid Power Association (NFPA), IFPE co-owner.

IFPE, the International Exposition for Power Transmission, will be the largest event in North America in 2008 for the motion control industry.

CONEXPO-CON/AGG will be the largest international exposition in 2008 for the construction industries.

“The IFPE exhibits complement the components section of CONEXPO-CON/AGG, providing added value to attendees and exhibitors alike.

CONEXPO-CON/AGG exhibitors also benefit by the convenient access that their engineers,

specifiers, R&D and other technical personnel have to the latest power transmission technologies,� said Megan

Tanel, CONEXPO-CON/AGG Director.

Strategic Planning Task Force Provides Vision for IFPE’s Future

The last IFPE, held in 2005, broke records for number of exhibitors and total exhibit space, and the combined shows had record attendance. To continue this momentum, the co-location agreement calls for formation of an IFPE strategic planning task force made up of NFPA Board members. NFPA has appointed the following industry executives to the task force:

David Anderson, President and CEO of Sauer-Danfoss, Lincolnshire, Illinois;

Marwan M. Kashkoush, Corporate Vice President-Worldwide Sales/Marketing of Parker Hannifin Corp., Cleveland, Ohio; and

Hans Zobel, President and CEO of Festo Corp., Hauppauge, New York.

“Our shows are directed by industry volunteers to keep them targeted to industry needs. This task force of NFPA leaders will help provide the vision for IFPE’s future, meeting the evolving global demands of the power transmission marketplace,� stated Sara Truesdale Mooney, IFPE Show Manager.

For more information, phone 414-298-4141 (toll free 800-867-6060) fax 414-272-2672, online at www.ifpe.com or

www.conexpoconagg.com.

IFPE 2008 to Feature Pavilion of Power Transmission Distributors Association Members

PTDA and IFPE Partnership Provides Value to Attendees, Exhibitors

The International Exposition for Power Transmission (IFPE) and the Power Transmission Distributors Association

(PTDA) have signed an agreement which will bring a PTDA-sponsored exhibits pavilion to IFPE 2008, strengthening the scope of the exposition and increasing the opportunities for customer interaction.

IFPE is held every three years and the next show will be March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, USA.

IFPE 2008 will feature the broad range of power transmission and motion control products delivered through hydraulic, pneumatic, mechanical and electrical technologies. The exposition will be the largest industry gathering in North America for the motion control industry.

PTDA has also signed on as a supporting organization of IPFE 2008 and has designated the show as the only U.S. exposition it will support in 2008. In addition, PTDA will hold several association meetings in conjunction with IFPE 2008.

PTDA also lent similar support to the last IFPE, held in 2005. For the 2008 IFPE, the association has substantially increased the expected size of its exhibits pavilion.

“We are very pleased that PTDA and its members will again participate in IFPE, especially with an increased level of support. They provide a valuable dimension to the exposition and reinforce the show as an industry gathering place,� stated Linda Western, Executive Director of the National Fluid Power Association (NFPA), IFPE’s co-owner.

IFPE 2008 is co-located with CONEXPO-CON/AGG 2008, which will be the largest international gathering place for the construction industries in 2008. The shows are expected to attract more than 125,000 visitors from around the world. IFPE also features a highly regarded technical conference on power transmission and motion control technology.

“Our partnership with IFPE provides an ideal opportunity for our members to expand their contacts with qualified industry buyers worldwide as well as network with peers and take advantage of the education programs offered,� stated Mary Sue Lyon, PTDA Executive Vice President.

For more information on attending or exhibiting, phone 414-298-4141 or toll free 800-867-6060, fax 414-272-2672 or online at www.conexpoconagg.com or

www.ifpe.com.

Chairman Selected for IFPE 2008, Sauer-Danfoss Executive Heads Show Management Committee

David Anderson, President and Chief Executive Officer of Sauer-Danfoss in Lincolnshire, Illinois has been named Chairman of the Management Committee of the 2008 International Exposition for Power Transmission (IFPE). He will lead a volunteer group of industry executives responsible for overall show planning. IFPE 2008 will be held March 11-15, 2008 at the Las Vegas Convention Center in Las Vegas, Nevada.

IFPE is the leading international exposition and technical conference devoted to power transmission and motion control through hydraulic, pneumatic, mechanical and electrical technologies. The trienniel event is co-located with the

CONEXPO-CON/AGG 2008 exposition for the construction industries.

35 Years of Industry Experience

David Anderson has more than 35 years of experience in the fluid power industry. He joined Sauer Danfoss in 1984 and held various senior management positions within the company, including Executive Vice President - Strategic Business Development, before being named President and CEO in July 2002. He also serves on the company’s Board of Directors and the board’s Executive Committee. Anderson is an officer of the National Fluid Power Association (NFPA), show co-owner.

IFPE 2008 Management Committee Named

Named as Vice Chairman of the IFPE 2008 Management Committee is Marwan

Kashkoush, Corporate Vice President, Worldwide Sales and Marketing of Parker Hannifin Corporation, Cleveland, Ohio.

Also serving on the IFPE 2008 Management Committee, in addition to David Anderson and Marwan

Kashkoush, are:

Richard Arter, Communications Manager of Sun Hydraulics Corp., Medina, Ohio;

Mark Johns, Mobile Hydraulics Director, Account Management and Marketing of Bosch Rexroth Corp., Fountain Inn, South Carolina;

Josh Keepman, Industrial Advertising Specialist of Gates Corp., Denver, Colorado;

Marcia Klein, Treasurer of Cassappa Corp., Batavia, Illinois;

Judy Krause, Director of Marketing of Hydraforce Inc., Lincolnshire, Illinois;

Susanne Nelson, Marketing Administrator of Sauer-Danfoss Inc., Minneapolis, Minnesota;

Christopher Olson, President of T-Lon Products Inc., Hartland, Wisconsin;

Dave Prevallet, President of Prevallet Technical Services, Laurens, South Carolina;

Jeanie Reed, Marketing Manager, Trade Shows of Eaton Corp., Eden Prairie, Minnesota;

John Strickland, Director, Marketing and Product Development of Fairfield Manufacturing Company Inc.,

Layfayette, Indiana;

Erin Thull, Services and Marketing Specialist of National Fluid Power Association, Milwaukee, Wisconsin;

Linda Western, Executive Director of National Fluid Power Association, Milwaukee, Wisconsin;

Barbara Yurisich, Marketing Staff Assistant of Parker Hannifin Corp., Lincolnshire, Illinois.

IFPE Show Manager is Sara Truesdale Mooney from the Association of Equipment Manufacturers

(AEM), show producer and co-owner.

For more information contact IFPE at phone 414-298-4141 or toll free 800-867-6060, fax 414-272-2672 or online at

www.ifpe.com.

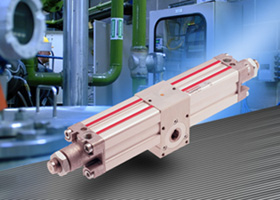

Detailed Parker Catalogue Provides Pneumatic Actuator Product Information

The Actuator Division of Parker Hannifin Corporation (NYSE:PH) recently released Pneumatic Actuator Products (AU03-0900P-3/NA), an updated,

comprehensive, 4-color, fully illustrated catalog. Pneumatic Actuator Products provides detailed information and complete specifications on Parker’s line

of pneumatic actuator products.

The catalog showcases important new products including the:

� P5L Series Guided Cylinder

� P5TT/D Series Twin Rod Cylinder

� P1D Series Rod Lock Cylinder

� P1X Series Rodless Cylinder

� P1Z Series Magnetically Coupled Rodless Cylinder

� PRNA Series Vane Rotary Actuator

This new edition of Pneumatic Actuator Products provides information about Parker Hannifin Compact Cylinders, Round Body Cylinders, ISO Cylinders,

Rodless Cylinders, Guided Cylinders, Rotary Actuators, Electronic Sensors, and Complementary Products. The catalog also includes engineering/safety

data and appropriate ordering information and forms.

The Pneumatic Actuator Products catalog features section-by-section updates with uniform product line presentation, easy-to-find model code layouts,

improved drawings and tables, as well as an entirely new subdivision on ISO cylinder products. All sections are fully illustrated with photos, flow charts,

diagrams and related schematics. All-new Application Fax Forms are included for four main product types, including cylinder, guided cylinder, rotary

actuator and gripper. As a result of field feedback, pagination has been simplified, with numbering by section rather than by product line.

Individual product chapters include product features, specifications, and full technical data to include performance curves, basic dimensions, options and

special modifications where applicable.

Global in scope as a supplier of pneumatic products and systems, Parker provides guidance throughout the catalog to help customers identify and apply

products. A full-color front section of the catalog features global capabilities, and a unique globe logo identifies products, services and manufacturing

facilities in multiple geographic regions.

The Actuator Division combines pneumatic, electromechanical, hydraulic and structural aluminum technologies to provide world-class automation system

solutions across all industries.

New Literature Release from ControlAir, Inc. New Literature Release from ControlAir, Inc.

ControlAir Inc. has released a redesigned Short Form Catalog which includes new products and industry approvals to its line of Precision Air Pressure Regulators, Transducers and Relays.

The redesigned catalog will provide customers with an easy, quick way to locate the most up-to-date product information, specifications and industry standards.

Regulators, transducers and relays are ideal for any pneumatic control system that requires precise regulation of air pressure in pipes and vessels. Applications include valve actuation, medical diagnostic instruments, web tensioning, roll loading, control panels, pneumatic counter balancers, test and lab apparatus, liquid dispensing machines, process control, robotics and leak testing equipment.

The units are offered in various pressure output ranges from 0 to 150 psi. Porting is 1/8�, 1/4", 3/8� NPT. All regulators come complete with 1/4" NPT gauge ports. Options include Tamperproof Cover and Factory Preset Output Pressures.

ControlAir Inc. manufactures precision pneumatic and electropneumatic controls. ControlAir’s markets include process control, semiconductor, printing and converting presses, diagnostic and surgical medical equipment, robotics, quality control, automotive, analyzers, compressors, pumps and paint equipment. For more information, ControlAir’s website,

www.controlair.com, offers full product specifications with pdf files, product CAD drawing files, and company profile.

ControlAir Inc. Phone: 603-886-9400

8 Columbia Drive Fax: 603-889-1844

Amherst, NH 03031 USA

Website: http://www.controlair.com

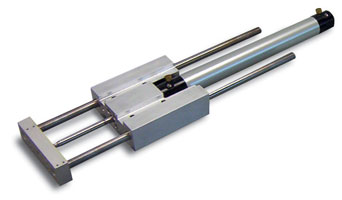

Quick-Ship Program for Parker P5L Cylinders Reduces Lead Times Quick-Ship Program for Parker P5L Cylinders Reduces Lead Times

The Actuator Division of Parker Hannifin Corporation (NYSE:PH) offers the P5L Series Quick-Ship Program for timely delivery of pneumatic cylinders. Using Quick-Ship, specific, stocked P5L guided cylinders ordered before 12 p.m. ET will ship the same day. Depending upon customer location, their orders will be received the following day. Today’s fast moving markets and compressed design cycles demand rapid response to reduce lead times.

The P5L Quick-Ship Program allows customers to electronically order by complete part number � simplifying the process and eliminating the need to configure. The program meets a variety of demanding requirements, including bore sizes 25, 32, 50, and 63mm and stroke lengths of 100, 200, and 300mm. The P5L Quick-Ship basic option set consists of:

� Thrust version

� Composite bushing

� Cushions

� Bumpers with adjustable stop collars

� Nitrile seals

� NPTF ports

The redesigned P5L Series of guided cylinders is engineered to deliver superior linear-motion performance for the most extreme applications. Coupled with the unique Quick-Ship Program, the P5L Series delivers precise performance and responds to compressed design cycles where quick delivery of critical components is crucial.

P5L cylinders feature two case-hardened support shafts directed by four linear bearings with all components incorporated into a one-piece housing. Bearing options include standard/oversized composite bushings with chrome-plated or stainless steel shafting or self-aligning and standard recirculating ball bearings with carbon or stainless steel shafting.

Versatile and full-featured, P5L’s guided bearing system makes it the system of choice for demanding applications such as pick-and-place assemblies, case erectors and gauging operations. Composite bushings are impregnated with Teflon to provide self-lubrication capabilities. Additional P5L options are available to customize applications to the most rigorous specs.

P5L Series� unparalleled features/benefits include self-aligning bearings for higher load capacities; micro-adjusters for high precision, accurate stroke; direct-mount cylinders for eliminating transition plates; and capacity to control loads of 9000N+ while 20-100 mm bores sizes are engineered to handle strokes in excess of

1500 mm.

The Actuator Division combines pneumatic, electromechanical, hydraulic and structural aluminum technologies to provide world-class automation system solutions across all industries.

DE-STA-CO

Establishes New Corporate Headquarters

DE-STA-CO, a worldwide leader in the innovation, design, manufacture and

support of clamping, gripping, transfer and robotic tooling solutions

for workplace and automation needs, has relocated its US headquarters to

Auburn Hills, Michigan in the Metropolitan Detroit area.

Effective February 5, 2007, the company will consolidate its

Birmingham and Madison Heights Industrial Workholding Products

operations and corporate offices to the larger, more modern facility.

The new headquarters will house the engineering, sales, manufacturing,

assembly, service, technical communications, training, marketing and

administration departments. Please note that this relocation only

affects corporate offices and Industrial Workholding Products

operations. DE-STA-CO Robohand Automation Products operations will

continue to be based out of Monroe, Connecticut.

The consolidation and move to the new location will allow for

additional efficiency of operations, as well as heightened communication

and accessibility for customers.

For more information on the new facility, please visit destaco.com

VP

Instruments ISO 9001:2000 certified VP

Instruments ISO 9001:2000 certified

VP Instruments, manufacturer of flowmeters for compressed air, is ISO-certified. The quality system was developed by our own quality manager Mr. D.

Grossklaus. This registration, issued by KEMA Quality B.V., recognizes VPInstruments� commitment to product quality and excellence in customer service.

ISO 9001:2000 is an internationally accepted reference for business-to-business quality management requirements. Certification is granted to organizations that demonstrate their ability to consistently fulfill customers' quality requirements and applicable regulatory requirements.

VPInstruments info@vpinstruments.com

Buitenwatersloot 335 www.vpinstruments.com

2614 GS Delft, the Netherlands

T:00 31 152131580

F:00 31 152130669

New catalog features Series QR1 Pneumatic Push-in Fittings New catalog features Series QR1 Pneumatic Push-in Fittings

Rexroth catalog SC-400.10 features inch and metric Series QR1 pneumatic push-in fittings

With the QR1 series, Rexroth provides a comprehensive inch and metric (ISO-G) program for its pneumatic components. In addition to the Mini and Standard programs, the complete fitting program also includes various function fittings.

Rexroth catalog SC-400.10 features 128 pages of technical and ordering information and a features overview section on Series QR1 pneumatic push-in fittings. Series QR1 (Quick Release) fittings are equipped with a user-friendly oval plastic release ring that enables fast connection and release of compressed air tubing, making them easier to use than standard push-in fittings.

The Mini design has been created for plastic tubing ODs of 1/8� to ¼” and 3-6 mm. This variety of fittings is completely new at Rexroth and rounds out the product spectrum specifically for the small handling sector. The Standard design fittings can be used for tubing ODs of 5/32� to ½” and 4-16 mm. Products such as check, ball and flow control valves are also included in the range of function fittings.

Rexroth

Norgren’s new look web store delivers online advantage

As the demand for online purchasing increases Norgren has enhanced its online web store facility to offer even more functionality. The existing online purchasing facility has undergone a major makeover in response to customer feedback and is now easier to use and features new innovative tools and services. Original Equipment Manufacturers are increasing the use of electronic media to provide support for designers and engineers alike. Competitive advantage can be achieved through the use of innovative services all targeted at cutting costs and reducing time to market.

With a new simpler, cleaner and fresher look the online facility benefits from a complete redesign that provides updated navigational features such as a new tab style menu and quick links thus ensuring speedy access to the sites main tools. The online catalogue proves a popular stop for most sites visitors and this has been redesigned to show clearer information. Offering real time price and availability information, the ability to track all orders however they are placed and a host of purchasing tools, the new store helps buyers and engineers get their job done more efficiently.

For more information or an online tour please visit http://store.norgren.com/US

Mead Fluid Dynamics, Inc. announces the formation of a New Division, MFD Pneumatics.

MFD Pneumatics will offer a new line of pneumatic valves, cylinders, filter regulators (FRL’s) and related components designed for OEM applications.

This new product line will offer low cost, quality pneumatic components designed to assist OEM’s with their most demanding and cost competitive product requirements.

For information call 1-866-264-9560 or visit www.mfdpneumatics.com

Beswick Engineering’s New Website Offers 3D Models for Download Beswick Engineering’s New Website Offers 3D Models for Download

Beswick Engineering designs and manufactures high-performance miniature fluid power devices.

Beswick Engineering’s new web site offers 3D models for download! The new site,

www.beswick.com, went live on the 9th of March 2006.

Many customers have transitioned from 2D drawings to 3D models to shorten their design cycle. 3D models help design engineers create their own assemblies, check potential

interferences, and create assembly drawings for manufacturing. Beswick will continue to provide 2D drawings for customers who require the 2D format.

In addition to the inclusion of 3D models, Beswick has optimized the web site for faster product searches. Over 200 new products have been added to the new website.

Applications include: medical and dental equipment, instruments, laboratory equipment, semiconductor manufacturing equipment, aerospace equipment, packaging machinery, industrial

robots and many more.

Beswick products include: fittings, valves, quick disconnects, pressure regulators/gauges, cylinders, filters, orifices, shock absorbers, pressure electric switches, tubing, etc.

Beswick speaks your language and can custom design products to meet your specific requirements.

For more information, please contact:

Applications Engineers

Beswick Engineering Co., Inc.

284 Ocean Road, Greenland, NH 03840-2442 USA

Phone: +1 603.433.1188

Fax: +1 603.433.3313

E-mail: besales@beswick.com

Website: http://www.beswick.com

Norgren’s new fluid control group combines a wealth of expertise Norgren’s new fluid control group combines a wealth of expertise

Littleton, Colorado, USA � Norgren has announced that it is combining the well established and proven brands of

FAS, Webber, Buschjost and KIP to form the new Norgren fluid control group. The new group will focus its energy and resources on fluid control valves and solutions and, by bringing these brands into one organization, will provide customers with the combined resources, expertise and breadth of product range to enable them to source any fluid control solution from one capable global supplier.

The new group benefits from over 100 engineers who are completely dedicated to the development of solenoid valves, process valves and customized fluid control solutions.

FAS, Webber, Buschjost and KIP have the project management experience, the specialized industry knowledge as well as an in depth understanding of standards. This expertise is utilized to create competitive advantage by actively helping customers to increase sales, improve market share and reduce total cost of ownership.

With a vast amount of experience in a wide variety of industry sectors such as medical, on board vehicle, inkjet, water management and environmental technology the group’s expertise lies in customizing a world leading portfolio of technologies into dedicated system solutions to overcome customer specific problems. As an IMI subsidiary, and part of the global Norgren organization, the new fluid control group provides customers worldwide with the reassurance of dealing with an established global supplier with financial strength and security, plus all the advantages of a global sales and service network.

� By bringing Norgren’s fluid control brands into one team means we are able to combine their extensive customer experience and technological capabilities to provide some very innovative solutions� said Sean Toomes managing director of the new fluid control group. � The engineers within the group are highly focused on providing solutions that deliver real engineering advantage. The teams capabilities and the results they deliver astonishes me�

The new group, headquartered in Switzerland, has a multi national approach with FAS located in Geneva, Buschjost in Germany, KIP in the USA and Webber based in the UK. From these facilities the group is able to offer both technical and manufacturing capabilities. For further information please visit

www.norgren.com

BISHOP-WISECARVER FOUNDER DONATES TIME, MONEY TO STUDENTS� SCIENCE AND ENGINEERING PURSUITS BISHOP-WISECARVER FOUNDER DONATES TIME, MONEY TO STUDENTS� SCIENCE AND ENGINEERING PURSUITS

Nearly 30 years ago, Bud Wisecarver, founder of Pittsburg’s Bishop-Wisecarver Corporation, began offering his engineering and manufacturing expertise in classrooms across the region.

On Friday, March 31, 2006, he continued the tradition at the First Annual Contra Costa Science & Engineering Fair, held at Heald College and Conference Center in Concord, CA.

Mr. Wisecarver served as a judge at the event, which showcased 94 projects created by 104 students from 15 Contra Costa schools. Students grades 7 through 12 were invited to compete in six categories: Behavioral and Social Sciences; Biological Sciences; Engineering; Environmental Sciences; Math and Computer Sciences and Physical Sciences.

In addition to donating time to the judging process, Bishop-Wisecarver Corporation was named a Gold Sponsor by contributing $1,000 to the event.

Projects ranged from simple to elaborate and tested everything from mold growth to levee construction. The fair gave students the opportunity to apply scientific knowledge and critical thinking skills and exercise creativity.

“The fair got a lot of people � students and teachers � involved,� Mr. Wisecarver said. “It gave many students a chance to compete.�

The winners of the Contra Costa Science & Engineering Fair will advance to the International Science & Engineering Fair, which will be held in Indianapolis, Ind., from May 7-13.

About Bishop-Wisecarver

Bishop-Wisecarver Corporation has remained one of the most respected names in guided motion technology since 1950. The San Francisco Bay Area company manufactures, stocks, and distributes guided motion components and systems for linear, rotary and curved track applications.

Bishop-Wisecarver products are used worldwide in industries such as packaging, medical device manufacturing, wood processing, food processing and semi-conductor fabrication.

Bishop-Wisecarver Corporation

(888) 580-8272 Toll Free

(925) 439-8272 Main

(925) 439-5931 Fax

PHD’s New 2006 Product Solutions Catalog Now Available PHD’s New 2006 Product Solutions Catalog Now Available

PHD has released its newly updated main product catalog, Catalog 2006 Solutions Book. The catalog allows users to have PHD’s current product information available within arm’s reach at all times. Catalog 2006 is yet another example of PHD’s commitment to excellence in product, service and support, and to provide customers with “Simple Productivity Solutions.�

Catalog 2006 contains the latest product information on PHD’s standard products including powered slides, grippers, rotary actuators, cylinders, multi-motion actuators, escapements, switches, and sensors. The catalog also contains information on newly released products including Series GRR Guardian� Grippers, new generation Series CR and CT Compact Cylinders, and more.

This year’s edition also provides more clamp products solutions as well as a section describing PHD’s Plastic Packaging Components Group. This group is dedicated to meeting the specific needs of the plastic packaging industry.

To request a free catalog, call PHD, Inc. at (800) 624-8511, or visit our website at

www.phdinc.com.

PHD, Inc., P.O. Box 9070, Fort Wayne, IN 46899

(260) 747-6151; FAX (260) 747-6754

www.phdinc.com

phdinfo@phdinc.com

PIAB NAMES MIKE BROTZ AUTOMOTIVE SEGMENT SPECIALIST PIAB NAMES MIKE BROTZ AUTOMOTIVE SEGMENT SPECIALIST

Hingham, MA, —PIAB Vacuum Products, a leading manufacturer of industrial vacuum products, has appointed Mike Brotz to the position of Automotive Segment Specialist. In his new role, Mr. Brotz will be responsible for overseeing all account activity in PIAB’s automotive segment, helping customers optimize their vacuum systems and ensure that the most productive and energy efficient solutions are in place.

Brotz will also work closely with PIAB’s North American distributors to provide technical and sales support and training for automotive-specific vacuum solutions. With over 20 years of experience working with those within the automotive manufacturing industry, Mr. Brotz brings a wealth of knowledge to companies that want to improve their existing systems and make investments for the future.

Previously, Mr. Brotz served as a District Sales Manager for PIAB in the company’s Southeast Michigan territory. Prior to PIAB Brotz worked for MRM Inc., a Michigan-based distributor of industrial automation products for the automotive industry.

About PIAB

PIAB Vacuum Products is a global leader in developing innovative vacuum products for use in automated material handling and factory automation processes. PIAB provides innovative solutions designed to help improve productivity and efficiency in manufacturing processes around the world.

For more information about PIAB’s complete line of products, contact, PIAB USA, Inc., 65 Sharp Street, Hingham, MA 02043, or call 1-800-321-7422; visit

www.piab.com

Blancett Flow Meters Receives $1.6 Million Dollar Military Contract

Racine, WI, December 1, 2005: Blancett Flow Meters, a division of Racine Federated Inc., has

been awarded a $1.6 million dollar military contract for the Model 1100 Turbine flow meter and B2800

flow monitor. These meters are part of a fuel transfer system used by the Department of Defense for

measurement of filling capacity and flow consumption. The contract began with one Blancett system

replacing an older structure that is currently in place. Due to the quality, accuracy and durability, the

Blancett flow meters were approved by procurement and all transfer fuel systems will be replaced

with the Blancett flow systems.

The Blancett turbine flow meter can be used in temperature ranges of -25 °F to +140 °F (-30 °C

to +60 °C), thus withstanding all global environments. The turbine meter consists of only one moving

part, thus reducing maintenance costs greatly. The system is part of caged construction assembly

that can be easily transported to measure the liquid flow in various pipe sizes. The B2800 is a

microprocessor-based flow monitor that displays the flow rate and the total calculated flow.

Dominic Cariello, General Manager of Blancett, has worked with this project in conjunction with

TTI, a Vermont based distributor of the Blancett product line. TTI will be providing the entire fuel

transfer system, which includes the Blancett turbine flow meters and monitors, to the Department of

Defense over the next six months. “This is a great opportunity for Blancett and Racine Federated Inc.

The Racine team is excited about this project and ready to provide quality products to the government,

says Cariello.

For additional information on any of the Blancett products, please feel free to contact us toll-free

at: (800)235-1638, visit us on-line at: www.blancett.com, or e-mail us at: info@blancett.com. Factory

trained customer service representatives are available to help in the selection process.

Grippers in Motion � The fascination of handling applications Grippers in Motion � The fascination of handling applications

New developments and technologies in the area of automation technology are part of our daily life. Besides the continuous changes of the technology itself, the general conditions for applications of automation components are constantly changing as well. Customers require precise and flexible solutions, which offer universal application possibilities.

The new specialized book “Grippers in Motion� offers a complete overview of state-of-the art technology in the automation sector. With many illustrations, the book explains the entire process starting with the basic requirements of the handling process and the history of automation technology up to the principal part of the entire process � the workpiece.

Let this book inspire you and explain the countless application possibilities of gripping technology. It will show you:

- Initial situation and limiting conditions of handling applications

- Stages of development and history of gripping systems and robots

- Gripping applications and workpieces

- Extensive chapter about real applications and completed projects

The book is available in book stores or can be ordered directly at SCHUNK for a price of $69.95.

- SCHUNK INC.

- 211

Kitty Hawk Drive

- Morrisville,

North Carolina 27560

- Phone:

919.572.2705 or

- 800.772.4865

- Fax:

919.572.2818

- www.schunk-usa.com

- info@schunk-usa.com

-

-

New Catalog From Techno-Sommer Automatic Features New Products To Provide Better Solutions New Catalog From Techno-Sommer Automatic Features New Products To Provide Better Solutions